Page 11 - Shroeder - Filter Systems

P. 11

Technical Cleanliness and

Contamination Management Basics

Consequences of

Particulate

Contamination

in Fluid Power

Systems

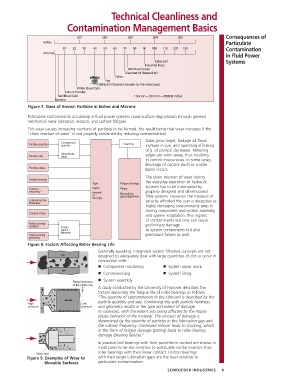

Figure 7. Sizes of Known Particles in Inches and Microns

Particulate contaminants circulating in fluid power systems cause surface degradation through general

mechanical wear (abrasion, erosion, and surface fatigue).

This wear causes increasing numbers of particles to be formed, the result being that wear increases if the

“chain reaction of wear” is not properly contained (by reducing contamination).

Gaps grow larger, leakage oil flows

increase in size, and operating efficiency

(e.g. of pumps) decreases. Metering

edges are worn away, thus resulting

in control inaccuracies. In some cases,

blockage of control ducts or nozzle

bores occurs.

The chain reaction of wear during

the everyday operation of hydraulic

systems has to be interrupted by

properly designed and dimensioned

filter systems. However, the measure of

security afforded the user is deceptive as

highly damaging contaminants seep in

during component and system assembly

and system installation. This ingress

of contaminants not only can cause

preliminary damage

to system components but also

premature failure as well.

Figure 8. Factors Affecting Roller Bearing Life

Generally speaking, integrated system filtration concepts are not

designed to adequately deal with large quantities of dirt as occur in

connection with:

■ Component machining ■ System repair work

■ Commissioning ■ System filling

■ System assembly

A study conducted by the University of Hanover describes the

factors impacting the fatigue life of roller bearings as follows:

“The quantity of contamination in the lubricant is described by the

particle quantity and size. Combining this with particle hardness

and geometry results in the type and extent of damage

to raceways, with the extent also being affected by the elasto-

plastic behavior of the material. The amount of damage is

determined by the quantity of particles in the lubrication gap and

the rollover frequency. Continued rollover leads to cracking, which

in the form of fatigue damage (pitting) leads to roller bearing

damage (bearing failure).”

In practice ball bearings with their punctiform contact are shown in

most cases to be less sensitive to particulate contamination than

roller bearings with their linear contact. Friction bearings

Figure 9. Examples of Wear to with their larger lubrication gaps are the least sensitive to

Movable Surfaces particulate contamination.

SCHROEDER INDUSTRIES 9