Page 12 - Parker - Assembly/Installation

P. 12

4300 Catalog Assembly / Installation

Tube End Assembly

Tube End Assembly A tube cutter may be used with soft tube such as copper and

aluminum. It is not recommended for steel and stainless steel

The assembly of the tube end consists of the following two tube because it creates a large burr on the I.D., which is difficult

steps: to remove and creates flow restriction. Furthermore, if the tube

1. Tube end preparation (cutting, deburring and cleaning) needs to be flared or flanged, the build up on the ID can com-

promise the sealing surface. For a steel or stainless steel tube

2. Assembly and installation application, Fig. S13 illustrates a proper cut and an improper cut

(the improper cut was performed by a tube cutter).

Tube End Preparation

Tube end preparation is a very critical step to assure the integrity

of a tube assembly. Failure to properly perform this function can

result in leakage. The three steps in proper tube end preparation

are: cutting, deburring and cleaning.

Cutting

Cut tube reasonably square (within +/- 1°) using a circular toothed

cut-off saw (see Fig. S11), or a hacksaw with a fine tooth blade

guided by a Tru-Cut Saw Guide (shown in Fig. S12) or other Improper Cut

mitre-type saw guide. Proper Cut

Fig. S13 – Samples of improper and proper cuts on

steel tube

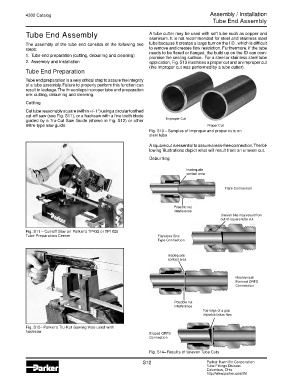

A square cut is essential to assure a leak-free connection. The fol-

lowing illustrations depict what will result from an uneven cut.

Deburring

Inadequate

contact area

Flare Connection

Possible nut

interference

Uneven bite may result from

out-of-square tube cut

Fig. S11 – Cut-off Saw on Parker’s TP432 or TP1025

Tube Preparation Center Flareless Bite

Type Connection

Inadequate

contact area

Mechanical

Formed ORFS

Connection

Possible nut

interference

Too large of a gap

impedes braze flow

Fig. S12– Parker’s Tru-Kut Sawing Vise used with

hacksaw Brazed ORFS

Connection

Fig. S14– Results of Uneven Tube Cuts

S12 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

http://www.parker.com/tfd