Page 23 - Paker - Medium Duty Hydraulic Cylinders

P. 23

Catalog HY08-1130-4/NA Medium Duty Hydraulic Cylinders

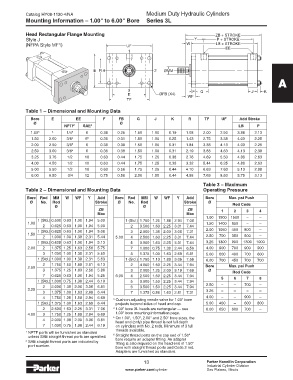

Mounting Information – 1.00" to 6.00" Bore Series 3L

Head Rectangular Flange Mounting ZB + STROKE

Style J Y P + STROKE

(NFPA Style MF1) UF W LB + STROKE

1 EE

E R 4 2 ØMM

A

3 F G J K

E ØFB (X4) WF

TF

Table 1 – Dimensional and Mounting Data

Bore E EE F FB G J K R TF UF Add Stroke

Ø Ø

NPTF 1 SAE 2 LB P

1.00 3 4 1/4 5 6 0.38 0.25 1.50 1.00 0.19 1.08 2.00 2.50 3.88 2.13

1.50 2.00 3/8 5 6 6 0.38 0.31 1.50 1.00 0.25 1.43 2.75 3.38 4.00 2.25

2.00 2.50 3/8 5 6 0.38 0.38 1.50 1.00 0.31 1.84 3.38 4.13 4.00 2.25

2.50 3.00 3/8 5 6 0.38 0.38 1.50 1.00 0.31 2.19 3.88 4.63 4.13 2.38

3.25 3.75 1/2 10 0.63 0.44 1.75 1.25 0.38 2.76 4.69 5.50 4.88 2.63

4.00 4.50 1/2 10 0.63 0.44 1.75 1.25 0.38 3.32 5.44 6.25 4.88 2.63

5.00 5.50 1/2 10 0.63 0.56 1.75 1.25 0.44 4.10 6.63 7.63 5.13 2.88

6.00 6.50 3/4 12 0.75 0.56 2.00 1.50 0.44 4.88 7.63 8.63 5.75 3.13

Table 3 – Maximum

Table 2 – Dimensional and Mounting Data Operating Pressure

Bore Rod MM W WF Y Add Bore Rod MM W WF Y Add Bore Max. psi Push

Ø No. Rod Stroke Ø No. Rod Stroke Ø

Ø Ø Rod Code

ZB ZB 1 2 3 4

Max Max

1.00 1900 1500 – –

1 (Std.) 0.500 0.63 1.00 1.94 5.00 1 (Std.) 1.750 1.25 1.88 2.94 7.06

1.00 1.50 1400 850 – –

2 0.625 0.63 1.00 1.94 5.00 2 3.500 1.63 2.25 3.31 7.44

1 (Std.) 0.625 0.63 1.00 1.94 5.06 3 2.000 1.38 2.00 3.06 7.31 2.00 1050 450 800 –

1.50 2.50 700 350 500 –

2 1.000 1.00 1.38 2.31 5.44 5.00 4 2.500 1.63 2.25 3.31 7.44

1 (Std.) 0.625 0.63 1.00 1.94 5.13 5 3.000 1.63 2.25 3.31 7.44 3.25 1300 900 1300 1000

2.00 2 1.375 1.25 1.63 2.56 5.75 7 1.000 0.75 1.38 2.44 6.56 4.00 900 700 900 900

3 1.000 1.00 1.38 2.31 5.50 8 1.375 1.00 1.63 2.69 6.81 5.00 600 400 700 600

1 (Std.) 1.000 1.00 1.38 2.31 5.63 1 (Std.) 1.750 1.13 1.88 3.06 7.56 6.00 700 450 700 700

2 1.750 1.50 1.88 2.81 6.13 2 4.000 1.50 2.25 3.44 7.94

2.50 Bore Max. psi Push

3 1.375 1.25 1.63 2.56 5.88 3 2.000 1.25 2.00 3.19 7.69 Ø Rod Code

7 0.625 0.63 1.00 1.94 5.25 6.00 4 2.500 1.50 2.25 3.44 7.94

1 (Std.) 1.000 0.75 1.38 2.44 6.19 5 3.000 1.50 2.25 3.44 7.94 5 6 7 8

2 2.000 1.38 2.00 3.06 6.81 6 3.500 1.50 2.25 3.44 7.94 2.50 – – 700 –

3.25 3.25 – – – –

3 1.375 1.00 1.63 2.69 6.44 7 1.375 0.88 1.63 2.81 7.31

4 1.750 1.25 1.88 2.94 6.69 3 Cushion adjusting needle valve for 1.00" bore 4.00 – – 900 –

1 (Std.) 1.375 1.00 1.63 2.69 6.44 projects beyond sides of head and cap. 5.00 450 – 600 800

2 2.500 1.63 2.25 3.31 7.06 4 1.00" bore 3L heads are rectangular — see 6.00 650 600 700 –

4.00 3 1.750 1.25 1.88 2.94 6.69 1.00" bore mounting information page.

5 On 1.00", 1.50", 2.00" and 2.50" bore sizes, the

4 2.000 1.38 2.00 3.06 6.81 head end (only) pipe thread is not full depth

7 1.000 0.75 1.38 2.44 6.19 on cylinders with No. 2 rods. Minimum of 3 full

threads available.

1 NPTF ports will be furnished as standard 6

unless SAE straight thread ports are specified. Straight thread ports on the cap end of 1.50"

2 SAE straight thread ports are indicated by bore require an adapter fitting. An adapter

fitting is also required on the head end of 1.50"

port number. bore with straight thread ports and Code 2 rod.

Adapters are furnished as standard.

13 Parker Hannifin Corporation

13

Industrial Cylinder Division

www.parker.com/cylinder Des Plaines, Illinois