Page 31 - Paker - Medium Duty Hydraulic Cylinders

P. 31

Catalog HY08-1130-4/NA Medium Duty Hydraulic Cylinders

Mounting Information – 1.00" to 5.00" Bore Series 3L

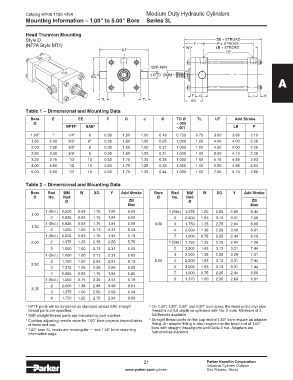

Head Trunnion Mounting

Style D ZB + STROKE

P + STROKE

(NFPA Style MT1) Y LB + STROKE

UT W EE

1

.125R MAX

E

SQ. 4 2 ØTD ØMM

A

3 F G J K

TL TL XG

Table 1 – Dimensional and Mounting Data

Bore E EE F G J K TD Ø TL UT Add Stroke

Ø +.000

NPTF 1 SAE 2 -.001 LB P

1.00 3 4 1/4 5 6 0.38 1.50 1.00 0.19 0.750 0.75 3.00 3.88 2.13

1.50 2.00 3/8 5 6 6 0.38 1.50 1.00 0.25 1.000 1.00 4.00 4.00 2.25

2.00 2.50 3/8 5 6 0.38 1.50 1.00 0.31 1.000 1.00 4.50 4.00 2.25

2.50 3.00 3/8 5 6 0.38 1.50 1.00 0.31 1.000 1.00 5.00 4.13 2.38

3.25 3.75 1/2 10 0.63 1.75 1.25 0.38 1.000 1.00 5.75 4.88 2.63

4.00 4.50 1/2 10 0.63 1.75 1.25 0.38 1.000 1.00 6.50 4.88 2.63

5.00 5.50 1/2 10 0.63 1.75 1.25 0.44 1.000 1.00 7.50 5.13 2.88

Table 2 – Dimensional and Mounting Data

Bore Rod MM W XG Y Add Stroke Bore Rod MM W XG Y Add Stroke

Ø No. Rod Ø No. Rod

Ø ZB Ø ZB

Max Max

1 (Std.) 0.500 0.63 1.75 1.94 5.00 1 (Std.) 1.375 1.00 2.50 2.69 6.44

1.00

2 0.625 0.63 1.75 1.94 5.00 2 2.500 1.63 3.13 3.31 7.06

1 (Std.) 0.625 0.63 1.75 1.94 5.06 4.00 3 1.750 1.25 2.75 2.94 6.69

1.50

2 1.000 1.00 2.13 2.31 5.44 4 2.000 1.38 2.88 3.06 6.81

1 (Std.) 0.625 0.63 1.75 1.94 5.13 7 1.000 0.75 2.25 2.44 6.19

2.00 2 1.375 1.25 2.38 2.56 5.75 1 (Std.) 1.750 1.25 2.75 2.94 7.06

3 1.000 1.00 2.13 2.31 5.50 2 3.500 1.63 3.13 3.31 7.44

1 (Std.) 1.000 1.00 2.13 2.31 5.63 3 2.000 1.38 2.88 3.06 7.31

2 1.750 1.50 2.63 2.81 6.13 5.00 4 2.500 1.63 3.13 3.31 7.44

2.50

3 1.375 1.25 2.38 2.56 5.88 5 3.000 1.63 3.13 3.31 7.44

7 0.625 0.63 1.75 1.94 5.25 7 1.000 0.75 2.25 2.44 6.56

1 (Std.) 1.000 0.75 2.25 2.44 6.19 8 1.375 1.00 2.50 2.69 6.81

2 2.000 1.38 2.88 3.06 6.81

3.25

3 1.375 1.00 2.50 2.69 6.44

4 1.750 1.25 2.75 2.94 6.69

1 NPTF ports will be furnished as standard unless SAE straight 5 On 1.00", 1.50", 2.00" and 2.50" bore sizes, the head end (only) pipe

thread ports are specified. thread is not full depth on cylinders with No. 2 rods. Minimum of 3

2 SAE straight thread ports are indicated by port number. full threads available.

3 Cushion adjusting needle valve for 1.00" bore projects beyond sides 6 Straight thread ports on the cap end of 1.50" bore require an adapter

of head and cap. fitting. An adapter fitting is also required on the head end of 1.50"

4 1.00" bore 3L heads are rectangular — see 1.00" bore mounting bore with straight thread ports and Code 2 rod. Adapters are

information page. furnished as standard.

21 Parker Hannifin Corporation

21

Industrial Cylinder Division

www.parker.com/cylinder Des Plaines, Illinois