Page 215 - Brass, Composite and Thermoplastic Fittings and Valves

P. 215

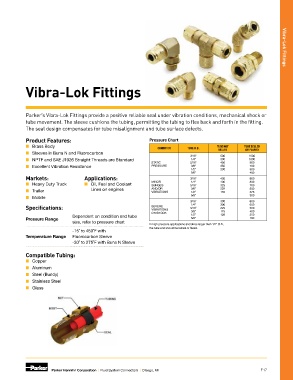

Vibra-Lok Fittings Vibra-Lok Fittings

Parker’s Vibra-Lok Fittings provide a positive reliable seal under vibration conditions, mechanical shock or

tube movement. The sleeve cushions the tubing, permitting the tubing to flex back and forth in the fitting.

The seal design compensates for tube misalignment and tube surface defects.

Product Features: Pressure Chart

■ Brass Body CONDITION TUBE O.D. TUBE NOT TUBE BELLED

OR FLARED

BELLED

■ Sleeves in Buna N and Fluorocarbon

3/16" 500 1000

■ NPTF and SAE J1926 Straight Threads are Standard 1/4" 500 1000

STATIC 5/16" 450 900

■ Excellent Vibration Resistance PRESSURE 3/8" 350 700

1/2" 200 500

5/8" 400

Markets: Applications: 3/16" 400 800

1/4"

■ Heavy Duty Truck ■ Oil, Fuel and Coolant MINOR 5/16" 400 800

325

SURGES

700

■ Trailer Lines on engines AND/OR 3/8" 225 500

375

1/2"

VIBRATIONS

150

■ Mobile 5/8" 300

3/16" 300 600

1/4"

Specifications: SEVERE 5/16" 300 600

500

225

VIBRATIONS

OR SHOCK 3/8" 175 400

Dependent on condition and tube 1/2" 100 250

Pressure Range 5/8" 100

size, refer to pressure chart

In high pressure applications and sizes larger than 1/2" O.D.,

the tube end should be belled or flared.

-15˚ to 450˚F with

Temperature Range Fluorocarbon Sleeve

-30˚ to 275˚F with Buna N Sleeve

Compatible Tubing:

■ Copper

■ Aluminum

■ Steel (Bundy)

■ Stainless Steel

■ Glass

Parker Hannifin Corporation | Fluid System Connectors | Otsego, MI F17