Page 473 - Wago_Rail-MountedTerminalBlockSystems_Volume1_2015_US.pdf

P. 473

"

– Description and Handling – 11

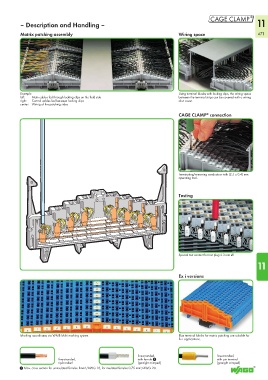

Matrix patching assembly Wiring space 471

Example Using terminal blocks with locking clips, the wiring space

left: Main cables fed through locking clips on the field side between the terminal strips can be covered with a wiring

right: Control cables fed between locking clips duct cover.

center: Wiring of the patching sides

CAGE CLAMP connection

®

Terminating/removing conductors with (2.5 x 0.4) mm

operating tool.

Testing

Special test contact for test plug 2.3 mm Ø.

11

Ex i versions

Marking coordinates via WMB Multi marking system. Blue terminal blocks for matrix patching are suitable for

Ex i applications.

fine-stranded, fine-stranded,

fine-stranded, with ferrule 1 with pin terminal

tip-bonded (gastight crimped) (gastight crimped)

1 Max. cross section for uninsulated ferrules 1mm²/AWG 18, for insulated ferrules 0.75 mm²/AWG 20.