Page 11 - Parker - Oil and Gas filtration and seperation solutions

P. 11

Feature Applications

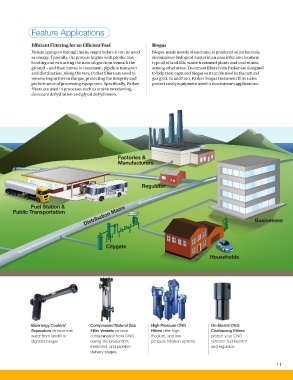

Efficient Filtering for an Efficient Fuel Biogas

Natural gas goes through many stages before it can be used Biogas, made mostly of methane, is produced when bacteria

as energy. Typically, the process begins with production – decomposes biological matter in an anaerobic environment

locating and extracting the natural gas from beneath the typical of landfills, waste treatment plants and coal mines,

ground – and then moves to treatment, pipeline transport among other areas. Treatment filters from Parker are designed

and distribution. Along the way, Parker filters are used to to help treat captured biogas so it can be used in the natural

remove impurities in the gas, protecting the integrity and gas grid. In addition, Parker biogas treatment filters also

performance of processing equipment. Specifically, Parker protect costly equipment used in downstream applications.

filters are used in processes such as amine sweetening,

desiccant dehydration and glycol dehydration.

Producing Wells

Factories &

Compressor Biogas Landfill Manufacturers

Stations Power Plant

Regulator

This bus runs

on CNG

Compressor

Stations

Fuel Station &

Public Transportation Distribution Mains

Processing Businesses

Plant

Underground

Storage

Citygate

Storage

Households

Bioenergy Coolers/ Compressed Natural Gas High Pressure CNG On-Board CNG

Separators remove free Filter Vessels remove Filters offer high, Coalescing Filters

water from landfill or contamination from CNG medium, and low protect your CNG

digester biogas. during the production, pressure filtration options. vehicles’ fuel injector

treatment, and pipeline and regulator.

delivery stages.

11