Page 8 - Parker - Oil and Gas filtration and seperation solutions

P. 8

Downstream

Downstream Processing

After upstream drilling and transport, crude oil must be Whether crude oil is being prepared

processed for use in an oil or petroleum refinery. Efficient for gasoline and diesel fuel or for

processing of several hundred thousand barrels of crude

oil a day – essentially a non-stop operation – demands olefins and aromatics, Parker filters

filtration solutions that perform reliably, even under are engineered to control, improve

extreme conditions. Parker meets the need with filtering and stabilize your processes.

systems that get the job done, and get finished product to

customers on time.

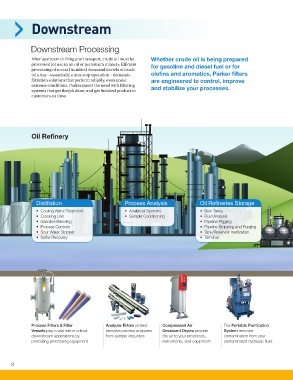

Oil Refinery

Distillation Process Analysis Oil Refineries Storage

• Cooling Water/Treatment • Analytical Systems • Bulk Tanks

• Cracking Unit • Sample Conditioning • Fluid Analysis

• Gasoline Blending • Pipeline Pigging

• Process Controls • Pipeline Stripping and Purging

• Sour Water Stripper • Tank/Reservoir Inertization

• Sulfur Recovery • Terminal

Process Filters & Filter Analyzer Filters protect Compressed Air The Portable Purification

Vessels play a vital role in critical sensitive process analyzers Desiccant Dryers provide System removes

downstream applications by from sample impurities. dry air to your processes, contamination from your

protecting processing equipment. instruments, and equipment. contaminated hydraulic fluid.

8