Page 7 - Parker - Oil and Gas filtration and seperation solutions

P. 7

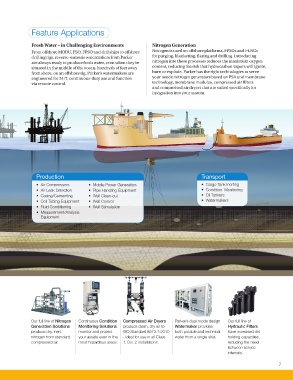

Feature Applications

Fresh Water – in Challenging Environments Nitrogen Generation

From offshore MODU, FSO, FPSO and drillships to offshore Nitrogen is used on offshore platforms, FPSOs and FLNGs

drilling rigs, reverse-osmosis watermakers from Parker for purging, blanketing, flaring and drilling. Introducing

are always ready to produce fresh water, even when they’re nitrogen into these processes reduces the maximum oxygen

situated in the middle of the ocean, hundreds of feet away content, reducing the risk that hydrocarbon vapors will ignite,

from shore, on an offshore rig. Parker’s watermakers are burn or explode. Parker has the right technologies to serve

engineered for 24/7, continuous-duty use and function your needs: nitrogen generators based on PSA and membrane

via remote control. technology, membrane modules, compressed air filters

and compressed air dryers that are suited specifically for

integration into your system.

Production Transport

• Air Compressors • Mobile Power Generation • Cargo Tank Inerting

• Air Leak Detection • Pipe Handling Equipment • Condition Monitoring

• Casing/Cementing • Well Clean-out • Oil Tankers

• Coil Tubing Equipment • Well Control • Watermakers

• Fluid Conditioning • Well Stimulation

• Measurement/Analysis

Equipment

Our full line of Nitrogen Continuous Condition Compressed Air Dryers Parker’s dual mode design Our full line of

Generation Solutions Monitoring Solutions produce clean, dry air to Watermaker provides Hydraulic Filters

produce dry, inert monitor and protect ISO Standard 8573.1:2010 both potable and technical have increased dirt

nitrogen from standard your assets even in the - ideal for use in all Class water from a single skid. holding capacities,

compressed air. most hazardous areas. 1, Div. 2 installations. reducing the need

between service

intervals.

7