Page 58 - Megaprojects Playbook

P. 58

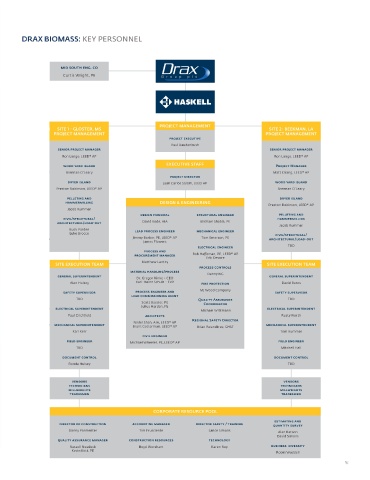

INFRASTRUCTURE AND UTILITIES DRAX BIOMASS: KEY PERSONNEL

Both projects consisted of all outdoor machines and large equipment that required cranes

for picking throughout the bulk of the project. Consequently most underground utilities were

impacted and damaged. Site logistics is not just the laydown area and trailer compound. mid south eng. co

Erection sequencing needs to be taken into account for open space campus builds. Curtis Wright, PE

STOREROOM FOR PROPER STORAGE OF SENSITIVE EQUIPMENT

Projects of this nature will have many devices, pumps and motors that need to be protected from the

elements. There will inevitably be a situation where you will have to receive deliveries of equipment that are

not ready for installation immediately. An organized, dry location for inventorying and proper checkout PROJECT MANAGEMENT

SITE 1 - GLOSTER, MS SITE 2- BEEKMAN, LA

will save the project from having to buy things twice due to weather damage or loss on-site. PROJECT MANAGEMENT PROJECT MANAGEMENT

project executive

Paul Raudenbush

senior project manager senior project manager

PROCESS GUARANTEES

Ron Longo, LEED® AP Ron Longo, LEED® AP

The process of converting lumber to pellets had several transfer points between OEMs. On the front wood yard island EXECUTIVE STAFF Project Manager

end the team worked through the process flow of throughput percentage guarantees per vendor to Brennan O’Leary project director Matt Chang, LEED® AP

make sure there were no bottlenecks in the system. However, more focus should have been given dryer island Juan Carlos Salom, LEED AP wood yard island

to the guarantee for throughput and downtime percentage. Based on the type of processing Preston Robinson, LEED® AP Brennan O’Leary

equipment we were installing; a 98% throughput 95% uptime, as example, is almost unachievable. pelleting and dryer island

hammermilling DESIGN & ENGINEERING

In the future, ranges should be the negotiated percentages we agree to with an owner. Preston Robinson, LEED® AP

Jacob Kummar

design principal structural engineer pelleting and

civil/structural/ hammermilling

architectural/load-out David Kode, AIA Michael Shabla, PE

Jacob Kummar

Buck Pardee lead process engineer mechanical engineer

Luke Brocco civil/structural/

Jimmy Barber, PE, LEED® AP Tom Emerson, PE architectural/load-out

James Flowers

electrical engineer TBD

process and

procurement manager Bob Haffeman, PE, LEED® AP

Eric Devore

Matthew Lantzy

SITE EXECUTION TEAM SITE EXECUTION TEAM

process controls

material handling/process

general superintendent Denny NG general superintendent

Dr. Gregor Rinke - CEO

Alan Hulsey Karl-Heinz Schulz - EVP fire protection David Bates

safety supervisor process engineer and MJ Wood Company safety supervisor

lead commissioning agent

TBD Quality Assurance TBD

Scott Baesler, PE Coordinator

Julius Harden, PE

electrical superintendent electrical superintendent

Michael Wittmann

Paul Crichfield architects Rusty North

Regional Safety Director

Nikhil Shah, AIA, LEED® AP

mechanical superintendent Brant Cotterman, LEED® AP Brian Roundtree, CHST mechanical superintendent

Karl Kerr Tom Kummer

civil engineer

field engineer Michael Wheeler, PE, LEED® AP field engineer

TBD Mitchell Hall

document control document control

Ronda Hulsey TBD

vendors vendors

technicians technicians

millwrights millwrights

tradesmen tradesmen

CORPORATE RESOURCE POOL

estimating and

director of construction accounting manager director safety / training quantity survey

Danny Parmenter Tim Frusciente Lance Simons

Alan Batson

David Simons

quality assurance manager construction resources technology

Russell Neudeck Boyd Worsham Karen Roy business diversity

Kevin Kett, PE

Robin Waddell

HASKELL | WE CREATE THINGS THAT MATTER 51