Page 53 - Megaprojects Playbook

P. 53

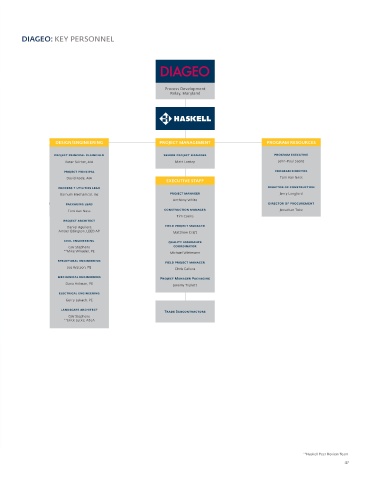

PHASED GMP SUBMISSIONS FOR EPC WORK DIAGEO: KEY PERSONNEL

Multi-disciplinary scope (facility, process, utilities & packaging) means we were responsible for the ripple

effects of changes between the scopes. When Haskell does not own the total scope, a variance to a piece of

packaging equipment (example: foundation or utility load) is passed back to the owner as a change order when

the change becomes known. When Haskell owns the total scope we're responsible for all of these variances

inside of our contract value, because we've committed to a GMP that incorporates contingency to manage all

of these changes. Consider phased GMPs by scope of work based on design completion. Adapt contingency Process Development

Relay, Maryland

to adequately address the risk of unforeseen changes that would not come through as a contract

change. Determine the appropriate levels by a risk review based on the level of scope completeness.

OWNER ASSIGNMENT

When Haskell agrees to incorporate equipment previously purchased by the client in our contract scope, we take on

DESIGN/ENGINEERING PROJECT MANAGEMENT PROGRAM RESOURCES

all risks of outcome even if we weren't initially responsible for the error. The Brenton Case packer was an unproven

technology for the application. It was selected and purchased initially by Diageo. We accepted the equipment into project principal plainfield senior project manager program executive

our contract, but advised that there was a high risk (both likelihood and impact) that the technology wouldn't Peter Skirbst, AIA Matt Lantzy John-Paul Saenz

work. The technology indeed did not work. However, because we accepted the scope inside of our contract we project principal program director

were responsible to make the necessary modifications and repairs, which resulted in high costs and ultimately David Kode, AIA Tom Van Ness

EXECUTIVE STAFF

damaged our reputation. Only accept assignment of owner purchased equipment if you can carve the risk out process + utilities lead director of construction

of the contract and/or have an opportunity to validate that it is the right application for our scope of work. Barnum Mechanical, Inc project manager Jerry Langford

Anthony White

packaging lead director of procurement

Tom Van Ness construction manager Jonathan Toke

Tim Coons

project architect

field project manager

Daniel Aguilera

Amber Edington, LEED AP Matthew Craft

civil engineering quality assurance

GW Stephens coordinator

**Mike Wheeler, PE

Michael Wittmann

structural engineering field project manager

Joe Watson, PE

Chris Callura

mechanical engineering Project Manager Packaging

Dana Helman, PE Jeremy Triplett

electrical engineering

Gerry Lukach, PE

landscape architect Trade Subcontractors

GW Stephens

**Erick Lycke, ASLA

**Haskell Peer Review Team

HASKELL | WE CREATE THINGS THAT MATTER 47