Page 54 - Megaprojects Playbook

P. 54

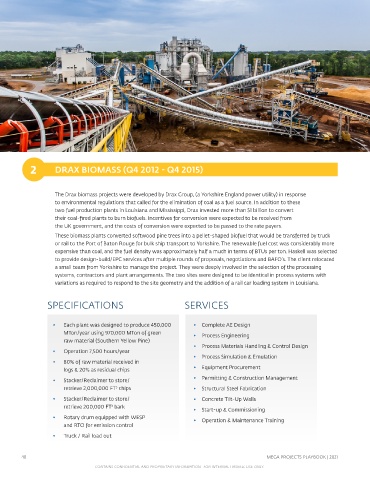

2 DRAX BIOMASS (Q4 2012 - Q4 2015)

The Drax biomass projects were developed by Drax Group, (a Yorkshire England power utility) in response

to environmental regulations that called for the elimination of coal as a fuel source. In addition to these

two fuel production plants in Louisiana and Mississippi, Drax invested more than $1 billion to convert

their coal-fired plants to burn biofuels. Incentives for conversion were expected to be received from

the UK government, and the costs of conversion were expected to be passed to the rate payers.

These biomass plants converted softwood pine trees into a pellet-shaped biofuel that would be transferred by truck

or rail to the Port of Baton Rouge for bulk ship transport to Yorkshire. The renewable fuel cost was considerably more

expensive than coal, and the fuel density was approximately half a much in terms of BTUs per ton. Haskell was selected

to provide design-build/EPC services after multiple rounds of proposals, negotiations and BAFO’s. The client relocated

a small team from Yorkshire to manage the project. They were deeply involved in the selection of the processing

systems, contractors and plant arrangements. The two sites were designed to be identical in process systems with

variations as required to respond to the site geometry and the addition of a rail car loading system in Louisiana.

SPECIFICATIONS SERVICES

◆ Each plant was designed to produce 450,000 ◆ Complete AE Design

MTon/year using 970,000 MTon of green ◆ Process Engineering

raw material (Southern Yellow Pine)

◆ Process Materials Handling & Control Design

◆ Operation 7,500 hours/year

◆ Process Simulation & Emulation

◆ 80% of raw material received in

logs & 20% as residual chips ◆ Equipment Procurement

◆ Stacker/Reclaimer to store/ ◆ Permitting & Construction Management

retrieve 2,000,000 FT chips ◆ Structural Steel Fabrication

3

◆ Stacker/Reclaimer to store/ ◆ Concrete Tilt-Up Walls

3

retrieve 200,000 FT bark

◆ Start-up & Commissioning

◆ Rotary drum equipped with WESP ◆ Operation & Maintenance Training

and RTO for emission control

◆ Truck / Rail load out

48 MEGA PROJECTS PLAYBOOK | 2021

CONTAINS CONFIDENTIAL AND PROPRIETARY INFORMATION. FOR INTERNAL HASKELL USE ONLY.