Page 375 - Mechatronics with Experiments

P. 375

October 9, 2014 8:1

Printer: Yet to Come

JWST499-c06

JWST499-Cetinkunt

SENSORS 361 254mm×178mm

Electromagnetic

field

Electrical

coil

Oscillator Detector Output

Target

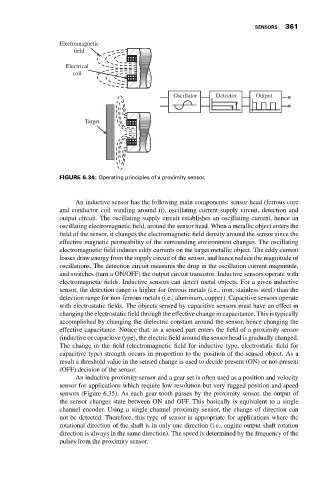

FIGURE 6.34: Operating principles of a proximity sensor.

An inductive sensor has the following main components: sensor head (ferrous core

and conductor coil winding around it), oscillating current supply circuit, detection and

output circuit. The oscillating supply circuit establishes an oscillating current, hence an

oscillating electromagnetic field, around the sensor head. When a metallic object enters the

field of the sensor, it changes the electromagnetic field density around the sensor since the

effective magnetic permeability of the surrounding environment changes. The oscillating

electromagnetic field induces eddy currents on the target metallic object. The eddy current

losses draw energy from the supply circuit of the sensor, and hence reduce the magnitude of

oscillations. The detection circuit measures the drop in the oscillation current magnitude,

and switches (turn a ON/OFF) the output circuit transistor. Inductive sensors operate with

electromagnetic fields. Inductive sensors can detect metal objects. For a given inductive

sensor, the detection range is higher for ferrous metals (i.e., iron, stainless steel) than the

detection range for non-ferrous metals (i.e., aluminum, copper). Capacitive sensors operate

with electrostatic fields. The objects sensed by capacitive sensors must have an effect in

changing the electrostatic field through the effective change in capacitance. This is typically

accomplished by changing the dielectric constant around the sensor, hence changing the

effective capacitance. Notice that, as a sensed part enters the field of a proximity sensor

(inductive or capacitive type), the electric field around the sensor head is gradually changed.

The change in the field (electromagnetic field for inductive type, electrostatic field for

capacitive type) strength occurs in proportion to the position of the sensed object. As a

result a threshold value in the sensed change is used to decide present (ON) or not-present

(OFF) decision of the sensor.

An inductive proximity sensor and a gear set is often used as a position and velocity

sensor for applications which require low resolution but very rugged position and speed

sensors (Figure 6.35). As each gear tooth passes by the proximity sensor, the output of

the sensor changes state between ON and OFF. This basically is equivalent to a single

channel encoder. Using a single channel proximity sensor, the change of direction can

not be detected. Therefore, this type of sensor is appropriate for applications where the

rotational direction of the shaft is in only one direction (i.e., engine output shaft rotation

direction is always in the same direction). The speed is determined by the frequency of the

pulses from the proximity sensor.