Page 376 - Mechatronics with Experiments

P. 376

JWST499-Cetinkunt

JWST499-c06

362 MECHATRONICS Printer: Yet to Come October 9, 2014 8:1 254mm×178mm

0.005 to 0.030 in

(0.13 to 0.76 mm)

On/off

sensor

0.081 in min

(2.1 mm) Gear

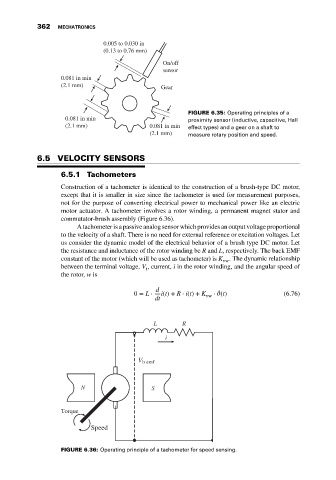

FIGURE 6.35: Operating principles of a

0.081 in min proximity sensor (inductive, capacitive, Hall

(2.1 mm) 0.081 in min effect types) and a gear on a shaft to

(2.1 mm) measure rotary position and speed.

6.5 VELOCITY SENSORS

6.5.1 Tachometers

Construction of a tachometer is identical to the construction of a brush-type DC motor,

except that it is smaller in size since the tachometer is used for measurement purposes,

not for the purpose of converting electrical power to mechanical power like an electric

motor actuator. A tachometer involves a rotor winding, a permanent magnet stator and

commutator-brush assembly (Figure 6.36).

A tachometer is a passive analog sensor which provides an output voltage proportional

to the velocity of a shaft. There is no need for external reference or excitation voltages. Let

us consider the dynamic model of the electrical behavior of a brush type DC motor. Let

the resistance and inductance of the rotor winding be R and L, respectively. The back EMF

constant of the motor (which will be used as tachometer) is K . The dynamic relationship

vw

between the terminal voltage, V , current, i in the rotor winding, and the angular speed of

t

the rotor, w is

d

̇

0 = L ⋅ i(t) + R ⋅ i(t) + K vw ⋅ (t) (6.76)

dt

L R

i

V b emf

N S

Torque

Speed

FIGURE 6.36: Operating principle of a tachometer for speed sensing.