Page 452 - Mechatronics with Experiments

P. 452

JWST499-Cetinkunt

JWST499-c07

438 MECHATRONICS Printer: Yet to Come October 9, 2014 8:41 254mm×178mm

Mechanical Pump Hydraulic

power power

Hydraulic

fluid inlet

(a)

P

l 2

P 3

P 1

P < P 1

3

T

(b)

P 2

P 3

P > P 1 P 1

3

P = P + P spring

2

3

T

(c)

P 2

P max

P 3

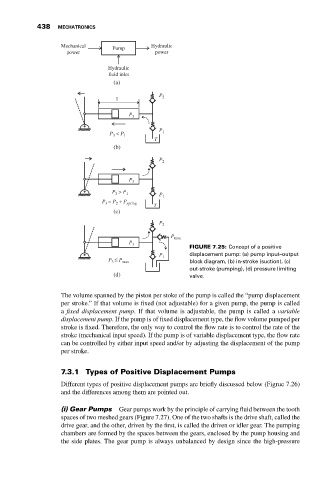

FIGURE 7.25: Concept of a positive

P 1 displacement pump: (a) pump input–output

P 3 ≤ P max block diagram, (b) in-stroke (suction), (c)

out-stroke (pumping), (d) pressure limiting

(d) valve.

The volume spanned by the piston per stoke of the pump is called the “pump displacement

per stroke.” If that volume is fixed (not adjustable) for a given pump, the pump is called

a fixed displacement pump. If that volume is adjustable, the pump is called a variable

displacement pump. If the pump is of fixed displacement type, the flow volume pumped per

stroke is fixed. Therefore, the only way to control the flow rate is to control the rate of the

stroke (mechanical input speed). If the pump is of variable displacement type, the flow rate

can be controlled by either input speed and/or by adjusting the displacement of the pump

per stroke.

7.3.1 Types of Positive Displacement Pumps

Different types of positive displacement pumps are briefly discussed below (Figrue 7.26)

and the differences among them are pointed out.

(i) Gear Pumps Gear pumps work by the principle of carrying fluid between the tooth

spaces of two meshed gears (Figure 7.27). One of the two shafts is the drive shaft, called the

drive gear, and the other, driven by the first, is called the driven or idler gear. The pumping

chambers are formed by the spaces between the gears, enclosed by the pump housing and

the side plates. The gear pump is always unbalanced by design since the high-pressure