Page 217 - Servo Motors and Industrial Control Theory -

P. 217

Appendix C 215

You should note that the amplitude of the voltage for each phase is taken as

220 V and for motors requiring lower voltage. A transformer may be used at the

input side to reduce the voltage to the required value.

You should also note that the gain around zero firing angle is very small and to

overcome this problem the thyristors are fired around 5–6° in both directions to

have reasonable gain at low firing angles.

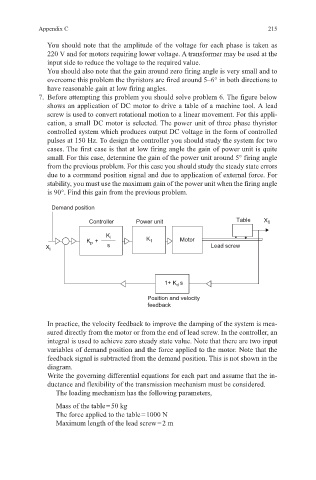

7. Before attempting this problem you should solve problem 6. The figure below

shows an application of DC motor to drive a table of a machine tool. A lead

screw is used to convert rotational motion to a linear movement. For this appli-

cation, a small DC motor is selected. The power unit of three phase thyristor

controlled system which produces output DC voltage in the form of controlled

pulses at 150 Hz. To design the controller you should study the system for two

cases. The first case is that at low firing angle the gain of power unit is quite

small. For this case, determine the gain of the power unit around 5° firing angle

from the previous problem. For this case you should study the steady state errors

due to a command position signal and due to application of external force. For

stability, you must use the maximum gain of the power unit when the firing angle

is 90°. Find this gain from the previous problem.

Demand position

Controller Power unit Table X 0

K i

K p + K 1 Motor

X i s Lead screw

1+ K d s

Position and velocity

feedback

In practice, the velocity feedback to improve the damping of the system is mea-

sured directly from the motor or from the end of lead screw. In the controller, an

integral is used to achieve zero steady state value. Note that there are two input

variables of demand position and the force applied to the motor. Note that the

feedback signal is subtracted from the demand position. This is not shown in the

diagram.

Write the governing differential equations for each part and assume that the in-

ductance and flexibility of the transmission mechanism must be considered.

The loading mechanism has the following parameters,

Mass of the table = 50 kg

The force applied to the table = 1000 N

Maximum length of the lead screw = 2 m