Page 233 - Servo Motors and Industrial Control Theory -

P. 233

Appendix C 231

F

ER Ruid

0V V+

The Gap

Inner Piston

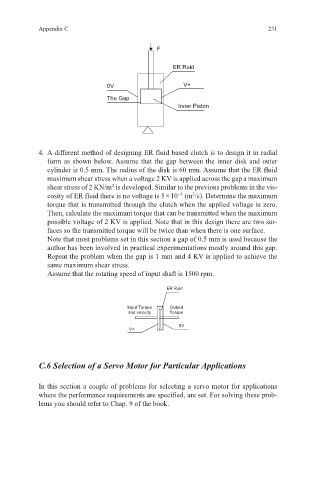

4. A different method of designing ER fluid based clutch is to design it in radial

form as shown below. Assume that the gap between the inner disk and outer

cylinder is 0.5 mm. The radius of the disk is 60 mm. Assume that the ER fluid

maximum shear stress when a voltage 2 KV is applied across the gap a maximum

2

shear stress of 2 KN/m is developed. Similar to the previous problems in the vis-

2

cosity of ER fluid there is no voltage is 5 × 10 (m /s). Determine the maximum

−5

torque that is transmitted through the clutch when the applied voltage is zero.

Then, calculate the maximum torque that can be transmitted when the maximum

possible voltage of 2 KV is applied. Note that in this design there are two sur-

faces so the transmitted torque will be twice than when there is one surface.

Note that most problems set in this section a gap of 0.5 mm is used because the

author has been involved in practical experimentations mostly around this gap.

Repeat the problem when the gap is 1 mm and 4 KV is applied to achieve the

same maximum shear stress.

Assume that the rotating speed of input shaft is 1500 rpm.

ER Ruid

Input Torque Output

and velocity Torque

0V

V+

C.6 Selection of a Servo Motor for Particular Applications

In this section a couple of problems for selecting a servo motor for applications

where the performance requirements are specified, are set. For solving these prob-

lems you should refer to Chap. 9 of the book.