Page 11 - Zero is Possible - Volume 3

P. 11

Figuil

Energy

Smart optimization in CAMEROON

cement grinding workshop Cement

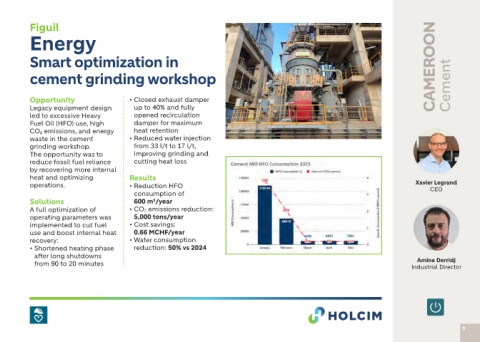

Opportunity • Closed exhaust damper

Legacy equipment design up to 40% and fully

led to excessive Heavy opened recirculation

Fuel Oil (HFO) use, high damper for maximum

CO₂ emissions, and energy heat retention

waste in the cement • Reduced water injection

grinding workshop. from 33 l/t to 17 l/t,

The opportunity was to improving grinding and

reduce fossil fuel reliance cutting heat loss

by recovering more internal

heat and optimizing Results

operations. • Reduction HFO Xavier Legrand

consumption of CEO

Solutions 600 m /year

3

A full optimization of • CO2 emissions reduction:

operating parameters was 5,000 tons/year

implemented to cut fuel • Cost savings:

use and boost internal heat 0.66 MCHF/year

recovery: • Water consumption

• Shortened heating phase reduction: 50% vs 2024

after long shutdowns

Amine Derridj

from 90 to 20 minutes Industrial Director

9