Page 14 - Zero is Possible - Volume 2

P. 14

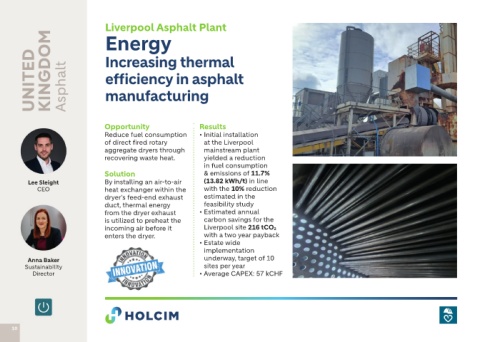

Liverpool Asphalt Plant

Energy

UNITED KINGDOM Asphalt Increasing thermal

efficiency in asphalt

manufacturing

Opportunity Results

Reduce fuel consumption • Initial installation

of direct fired rotary at the Liverpool

aggregate dryers through mainstream plant

recovering waste heat. yielded a reduction

in fuel consumption

Solution & emissions of 11.7%

Lee Sleight By installing an air-to-air (13.82 kWh/t) in line

CEO heat exchanger within the with the 10% reduction

dryer’s feed-end exhaust estimated in the

duct, thermal energy feasibility study

from the dryer exhaust • Estimated annual

is utilized to preheat the carbon savings for the

incoming air before it Liverpool site 216 tCO2

enters the dryer. with a two year payback

• Estate wide

implementation

Anna Baker underway, target of 10

Sustainability sites per year

Director • Average CAPEX: 57 kCHF

10