Page 77 - GuardII+ Series 4208 Platform EV User Manual

P. 77

Appendix

8.4. Modbus Slave Timing

NOTE:

As described in Section 4.2, GuardII+ updates the EV Modbus data

registers after every measurement cycle, which occurs every 6-10

seconds; however, polling the monitor too quickly is just wasting network

bandwidth.

Each monitoring technology in the GuardII+ Series 4208 Platform has its

own measurement cycle; so If the monitor has other monitoring

technologies installed, those other technologies may provide Modbus

updates more rapidly.

To achieve the best performance when polling GuardII+’s EV Modbus data registers, the

following configurations of the polling system should be used:

• Modbus response timeout should be set to no less than 5000ms

• Modbus polling should occur no more often than once every 5 seconds.

8.5. Using PLC-Style Addressing

GuardII+ uses protocol-style Modbus addressing (Base 0), not PLC-style Modbus

addressing (Base 1). When using PLC-style addressing to acquire Modbus data from

GuardII+, this will cause an address shift.

NOTE:

When accessing GuardII+ data registers using PLC-style addressing, the

address must be increased by 1.

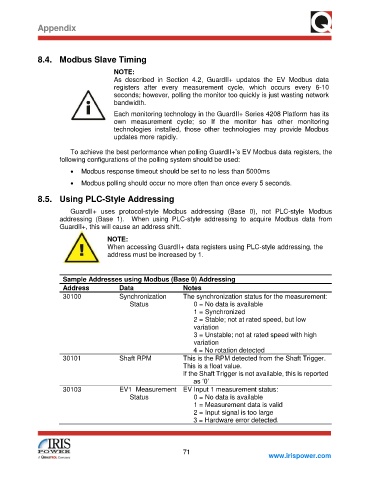

Sample Addresses using Modbus (Base 0) Addressing

Address Data Notes

30100 Synchronization The synchronization status for the measurement:

Status 0 = No data is available

1 = Synchronized

2 = Stable; not at rated speed, but low

variation

3 = Unstable; not at rated speed with high

variation

4 = No rotation detected

30101 Shaft RPM This is the RPM detected from the Shaft Trigger.

This is a float value.

If the Shaft Trigger is not available, this is reported

as ‘0’

30103 EV1 Measurement EV Input 1 measurement status:

Status 0 = No data is available

1 = Measurement data is valid

2 = Input signal is too large

3 = Hardware error detected.

71

www.irispower.com