Page 14 - GuardII+ Series 4208 Platform Flux User Manual

P. 14

GuardII+ Flux Card Operation

NOTE:

When a GuardII+ includes other technologies such as partial discharge

monitoring or endwinding vibration monitoring, the flux measurement cycle

time will not be significantly affected by these other monitoring

technologies.

4.3. Synchronization

To properly identify the poles, a synchronization source is used; the recommended source

is a shaft trigger (or keyphasor) signal. The shaft trigger is a proximity switch that provides a

once-per-revolution signal when it detects a target on the machine shaft such as a small

rubber or metallic square.

If a shaft trigger signal is not available, an alternative is to synchronize from the ac power

that is running the monitor.

NOTE:

When using ac synchronization, the GuardII+ will not be able to

consistently and reliably identify the machines’ poles. To accurately

identify which pole(s) are shorted on these machines, a shaft trigger signal

is required.

4.4. Operating Conditions

Measurement results can be affected by the current Operating Conditions of the asset

such as voltage, active power/load, temperature, humidity, etc. Operating Conditions help

when analyzing collected data.

There are two available sources of Operating Condition data:

• Directly from a Modbus slave

• From a Remote I/O Unit (optionally included with the GuardII+)

The following operating conditions can be measured by the flux monitoring; each can be

acquired from either a Modbus slave or a Remote I/O Unit.

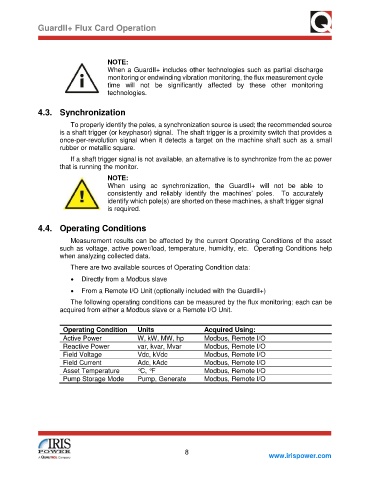

Operating Condition Units Acquired Using:

Active Power W, kW, MW, hp Modbus, Remote I/O

Reactive Power var, kvar, Mvar Modbus, Remote I/O

Field Voltage Vdc, kVdc Modbus, Remote I/O

Field Current Adc, kAdc Modbus, Remote I/O

Asset Temperature °C, °F Modbus, Remote I/O

Pump Storage Mode Pump, Generate Modbus, Remote I/O

8

www.irispower.com