Page 19 - january

P. 19

PRODUCTION AUTOMATION

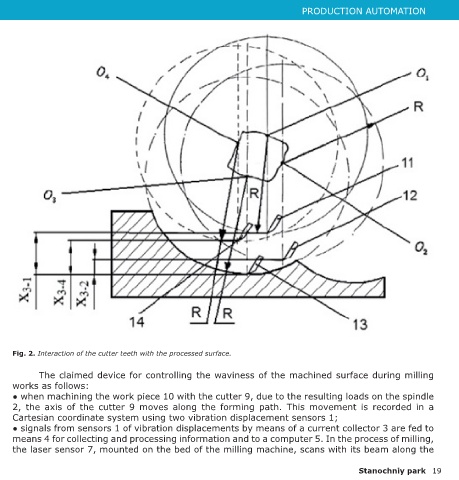

Fig. 2. Interaction of the cutter teeth with the processed surface.

The claimed device for controlling the waviness of the machined surface during milling

works as follows:

● when machining the work piece 10 with the cutter 9, due to the resulting loads on the spindle

2, the axis of the cutter 9 moves along the forming path. This movement is recorded in a

Cartesian coordinate system using two vibration displacement sensors 1;

● signals from sensors 1 of vibration displacements by means of a current collector 3 are fed to

means 4 for collecting and processing information and to a computer 5. In the process of milling,

the laser sensor 7, mounted on the bed of the milling machine, scans with its beam along the

Stanochniy park 19