Page 24 - january

P. 24

METALWORKING EQUIPMENT AND TOOLS

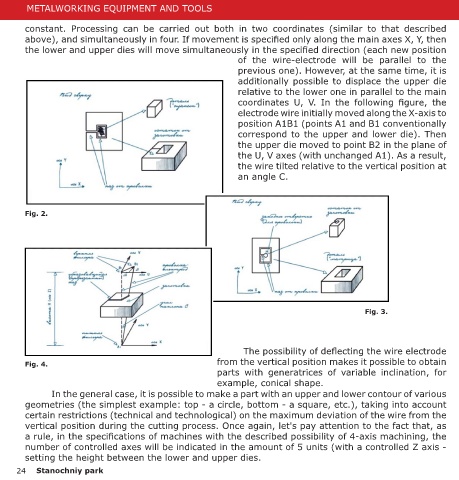

constant. Processing can be carried out both in two coordinates (similar to that described

above), and simultaneously in four. If movement is specified only along the main axes X, Y, then

the lower and upper dies will move simultaneously in the specified direction (each new position

of the wire-electrode will be parallel to the

previous one). However, at the same time, it is

additionally possible to displace the upper die

relative to the lower one in parallel to the main

coordinates U, V. In the following figure, the

electrode wire initially moved along the X-axis to

position A1B1 (points A1 and B1 conventionally

correspond to the upper and lower die). Then

the upper die moved to point B2 in the plane of

the U, V axes (with unchanged A1). As a result,

the wire tilted relative to the vertical position at

an angle C.

Fig. 2.

Fig. 3.

The possibility of deflecting the wire electrode

Fig. 4. from the vertical position makes it possible to obtain

parts with generatrices of variable inclination, for

example, conical shape.

In the general case, it is possible to make a part with an upper and lower contour of various

geometries (the simplest example: top - a circle, bottom - a square, etc.), taking into account

certain restrictions (technical and technological) on the maximum deviation of the wire from the

vertical position during the cutting process. Once again, let's pay attention to the fact that, as

a rule, in the specifications of machines with the described possibility of 4-axis machining, the

number of controlled axes will be indicated in the amount of 5 units (with a controlled Z axis -

setting the height between the lower and upper dies.

24 Stanochniy park