Page 27 - january

P. 27

METALWORKING EQUIPMENT AND TOOLS

The SPD method is simple to implement,

economical, has high productivity, allows to

provide low roughness and a given degree of

hardening, forms useful residual compressive

stress and other indicators of surface quality.

To carry out experiments on surface

hardening of the guide vanes by surface

plastic deformation, a technology was developed

for automated hardening processing of parts made of

powder alloys. A special device for hardening roller rolling

was designed and manufactured, which allows, thanks to the spring

mechanism, to change the roller clamping force during rolling. A special mandrel has been

developed and manufactured, which allows fixing the

workpiece with the minimum allowable runout. It has

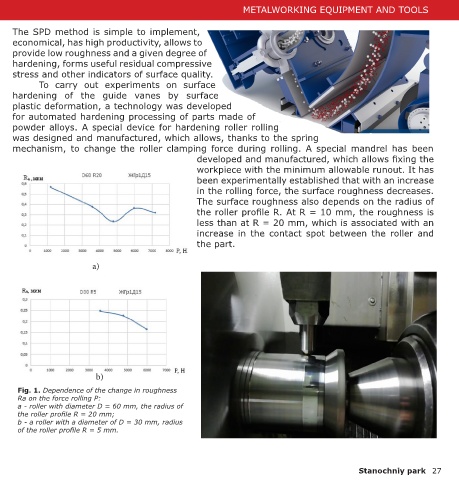

been experimentally established that with an increase

in the rolling force, the surface roughness decreases.

The surface roughness also depends on the radius of

the roller profile R. At R = 10 mm, the roughness is

less than at R = 20 mm, which is associated with an

increase in the contact spot between the roller and

the part.

а)

b)

Fig. 1. Dependence of the change in roughness

Ra on the force rolling P:

a - roller with diameter D = 60 mm, the radius of

the roller profile R = 20 mm;

b - a roller with a diameter of D = 30 mm, radius

of the roller profile R = 5 mm.

Stanochniy park 27