Page 42 - Dec 2022

P. 42

The Lat he, continued from page 41

and start (only start) the threads on each end.

I repaired to my garage and proceeded to use the old

South Bend to carefully finish cutting the threads on

each stud to snuggly fit the holes in the block. Strict

attention also had to be paid to the overall length of

each stud as they were ?captured? between the

?acorn? head nuts and the blind holes at the bottom

of the block.

Further , four of the long studs had to be a bit longer

than the rest to accommodate the engine lift fittings

which were installed under head nuts at four

locations ?details , details.

After completing this long, tedious, process I re-fitted

the various studs in the correct locations and

installed the head. Finally, using my own peculiar

procedure, I torqued it down and , voila, no leaks!

The St ripped Spark Plug Hole

The other project worthy of mention has to do with

the bane of all alloy cylinder heads ? the stripped

spark plug hole. Jaguar even anticipated this and in

their factory manuals they describe, and diagram,

fitting an insert to correct the problem. Trouble was,

to my knowledge, they never made any of these

inserts as repair parts.

Coils and thin steel inserts had all been tried and

failed. The fact that plugs are routinely removed and

replaced for a variety of reasons was just too much

for them. So , after studying the Jaguar diagrams I

decided to try and fabricate the type insert they were

talking about.

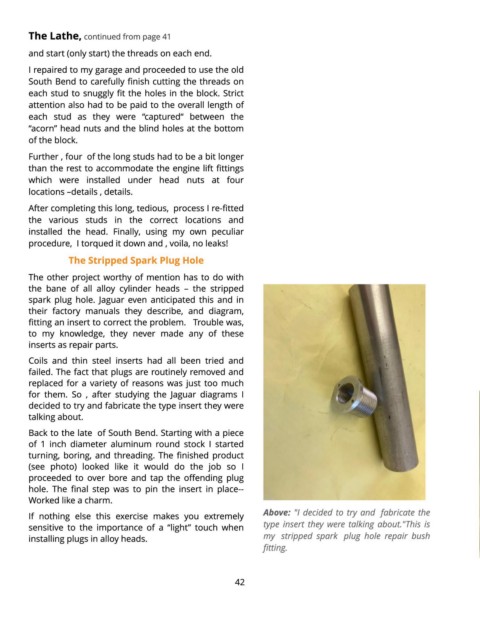

Back to the late of South Bend. Starting with a piece

of 1 inch diameter aluminum round stock I started

turning, boring, and threading. The finished product

(see photo) looked like it would do the job so I

proceeded to over bore and tap the offending plug

hole. The final step was to pin the insert in place--

Worked like a charm.

Above: "I decided to try and fabricate the

If nothing else this exercise makes you extremely

sensitive to the importance of a ?light? touch when type insert they were talking about."This is

installing plugs in alloy heads. my stripped spark plug hole repair bush

Petrol Powered fitting.

Performance, all the

Time 42