Page 12 - the story of motoring

P. 12

Henry Ford

Henry Ford rade two important changes in the story of motoring. He produced the

first cheap family car, the Model T. He also mass produced his cars on a mbving

assembly line.

Henry was the son of a farmer and his father expected him to stay on the farm. They

lived near Chicago in the U.S.A. Henry was very interested in anything mechanical.

He built his first car out of odds and ends. It was no more than a wooden box on

four wheels and a little engine. He continued to improve each car he built. Soon

he had a car that was good enoqgh for racing. After winning a few races the orders

for cars flooded in. So Henry started his own company - the Ford Motor Company.

In the pioneer days.cars were hand built. The car would be assembled in the middle

of a workshop and the mechanics would do the moving about. Cars therefore took a

long time to make and were expensive. Ford decided this was not the way to make a

car for the world at a price they could afford.

Mass production in industry had existed long before Ford. However he used these

ideas in car making. A huge factory was built at Detroit and the production of the

Model T began there in 1908. At first only the components were assembled on a moving

conveyor line. The line was speeded up to see how fast people could work and what

height was best. By 1913 a whole car could be built on the assembly line.

Ford In 1914 Ford shook America by offering wages of five

dollars a day. This was twice as much as other car

workers got. Ford also shortened the working day from

nine hours to eight. The crowds that turned up at the

factory finally had to be dispersed by waterhoses.

The Ford Company was soon making and selling millions

of cars. A second factory was built. It was enormous,

the biggest in the world. There were docks, steel works

and assembly plant. Iron was delivered at one end of

the site, melted down, moulded and converted into a fin-

ished car in 28 hours.

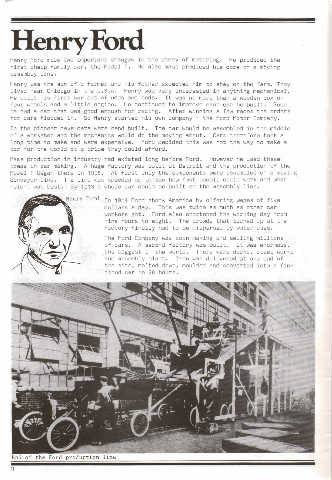

ona or me rord producrlon line - ..

-- -

11