Page 27 - Wayne Keating

P. 27

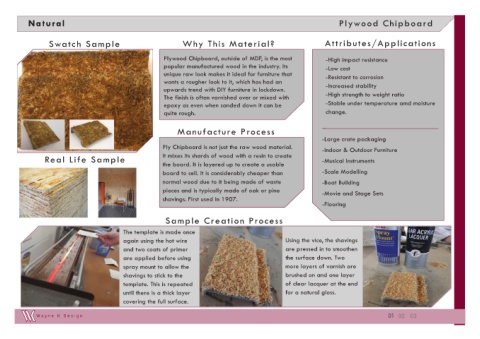

Natural Plywood Chipboard

Swatch Sample Why This Material? Attributes/Applications

Plywood Chipboard, outside of MDF, is the most -High impact resistance

popular manufactured wood in the industry. Its -Low cost

unique raw look makes it ideal for furniture that -Resistant to corrosion

wants a rougher look to it, which has had an

upwards trend with DIY furniture in lockdown. -Increased stability

The finish is often varnished over or mixed with -High strength to weight ratio

epoxy as even when sanded down it can be -Stable under temperature amd moisture

quite rough. change.

Manufacture Process

-Large crate packaging

Ply Chipboard is not just the raw wood material. -Indoor & Outdoor Furniture

Real Life Sample It mixes its shards of wood with a resin to create -Musical Instruments

the board. It is layered up to create a usable

board to sell. It is considerably cheaper than -Scale Modelling

normal wood due to it being made of waste -Boat Building

pieces and is typically made of oak or pine -Movie and Stage Sets

shavings. First used in 1907.

-Flooring

Sample Creation Process

The template is made once

again using the hot wire Using the vice, the shavings

and two coats of primer are pressed in to smoothen

are applied before using the surface down. Two

spray mount to allow the more layers of varnish are

shavings to stick to the brushed on and one layer

template. This is repeated of clear lacquer at the end

until there is a thick layer for a natural gloss.

covering the full surface.

W a yn e K Des ign 01 02 03