Page 28 - Wayne Keating

P. 28

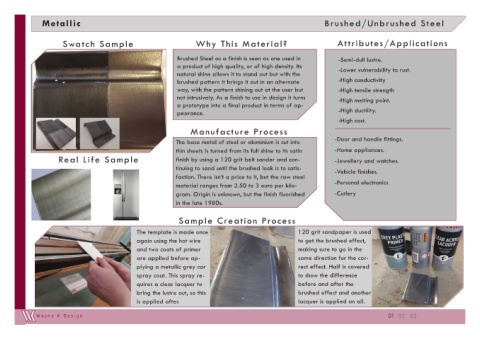

Metallic Brushed/Unbrushed Steel

Swatch Sample Why This Material? Attributes/Applications

Brushed Steel as a finish is seen as one used in -Semi-dull lustre.

a product of high quality, or of high density. Its -Lower vulnerability to rust.

natural shine allows it to stand out but with the

brushed pattern it brings it out in an alternate -High conductivity

way, with the pattern shining out at the user but -High tensile strength

not intrusively. As a finish to use in design it turns -High melting point.

a prototype into a final product in terms of ap-

pearance. -High ductility.

-High cost.

Manufacture Process

-Door and handle fittings.

The base metal of steel or aluminium is cut into

thin sheets is turned from its full shine to its satin -Home appliances.

Real Life Sample finish by using a 120 grit belt sander and con- -Jewellery and watches.

tinuing to sand until the brushed look is to satis- -Vehicle finishes.

faction. There isn’t a price to it, but the raw steel

material ranges from 2.50 to 3 euro per kilo- -Personal electronics

gram. Origin is unknown, but the finish fluorished -Cutlery

in the late 1980s.

Sample Creation Process

The template is made once 120 grit sandpaper is used

again using the hot wire to get the brushed effect,

and two coats of primer making sure to go in the

are applied before ap- same direction for the cor-

plying a metallic grey car rect effect. Half is covered

spray coat. This spray re- to show the difference

quires a clear lacquer to before and after the

bring the lustre out, so this brushed effect and another

is applied after. lacquer is applied on all.

W a yn e K Des ign 01 02 03