Page 16 - May

P. 16

METALWORKING EQUIPMENT AND TOOLS

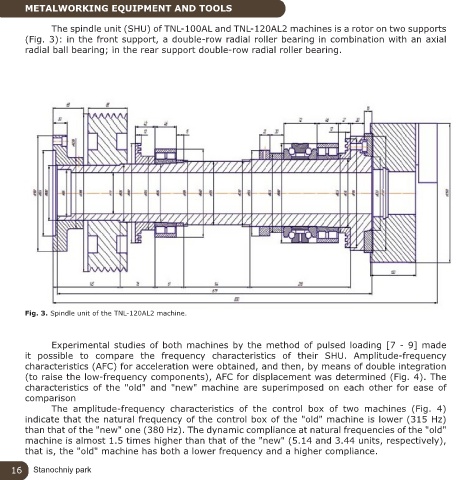

The spindle unit (SHU) of TNL-100AL and TNL-120AL2 machines is a rotor on two supports

(Fig. 3): in the front support, a double-row radial roller bearing in combination with an axial

radial ball bearing; in the rear support double-row radial roller bearing.

Fig. 3. Spindle unit of the TNL-120AL2 machine.

Experimental studies of both machines by the method of pulsed loading [7 - 9] made

it possible to compare the frequency characteristics of their SHU. Amplitude-frequency

characteristics (AFC) for acceleration were obtained, and then, by means of double integration

(to raise the low-frequency components), AFC for displacement was determined (Fig. 4). The

characteristics of the "old" and "new" machine are superimposed on each other for ease of

comparison

The amplitude-frequency characteristics of the control box of two machines (Fig. 4)

indicate that the natural frequency of the control box of the "old" machine is lower (315 Hz)

than that of the "new" one (380 Hz). The dynamic compliance at natural frequencies of the "old"

machine is almost 1.5 times higher than that of the "new" (5.14 and 3.44 units, respectively),

that is, the "old" machine has both a lower frequency and a higher compliance.

16 Stanochniy park