Page 18 - May

P. 18

METALWORKING EQUIPMENT AND TOOLS

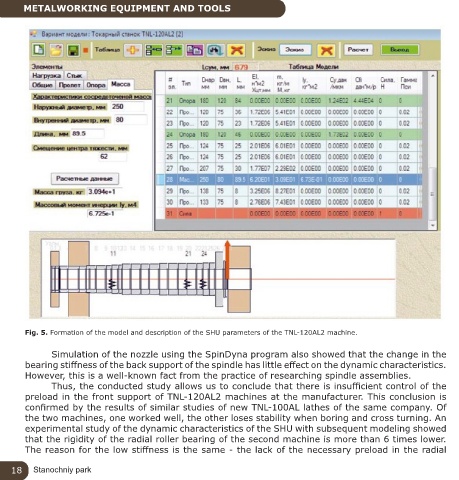

Fig. 5. Formation of the model and description of the SHU parameters of the TNL-120AL2 machine.

Simulation of the nozzle using the SpinDyna program also showed that the change in the

bearing stiffness of the back support of the spindle has little effect on the dynamic characteristics.

However, this is a well-known fact from the practice of researching spindle assemblies.

Thus, the conducted study allows us to conclude that there is insufficient control of the

preload in the front support of TNL-120AL2 machines at the manufacturer. This conclusion is

confirmed by the results of similar studies of new TNL-100AL lathes of the same company. Of

the two machines, one worked well, the other loses stability when boring and cross turning. An

experimental study of the dynamic characteristics of the SHU with subsequent modeling showed

that the rigidity of the radial roller bearing of the second machine is more than 6 times lower.

The reason for the low stiffness is the same - the lack of the necessary preload in the radial

18 Stanochniy park