Page 23 - May

P. 23

METALWORKING EQUIPMENT AND TOOLS

realized using the Siemens CNC system. Figure 3 shows the design of a machine table with a

direct drive 1 of the rotation of the spindle 2 with a work piece installed in it. The rotor 1 of

the electric motor is mounted on the glass 3, which is rigidly connected with the spindle by the

coupling 4. The stator of the motor 5 is fixed on the fixed part of the table.

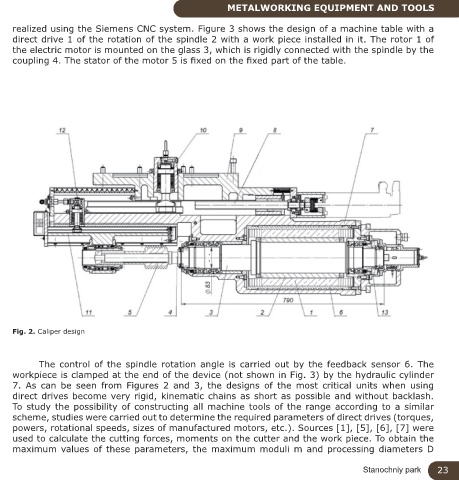

Fig. 2. Caliper design

The control of the spindle rotation angle is carried out by the feedback sensor 6. The

workpiece is clamped at the end of the device (not shown in Fig. 3) by the hydraulic cylinder

7. As can be seen from Figures 2 and 3, the designs of the most critical units when using

direct drives become very rigid, kinematic chains as short as possible and without backlash.

To study the possibility of constructing all machine tools of the range according to a similar

scheme, studies were carried out to determine the required parameters of direct drives (torques,

powers, rotational speeds, sizes of manufactured motors, etc.). Sources [1], [5], [6], [7] were

used to calculate the cutting forces, moments on the cutter and the work piece. To obtain the

maximum values of these parameters, the maximum moduli m and processing diameters D

Stanochniy park 23