Page 27 - May

P. 27

METALWORKING EQUIPMENT AND TOOLS

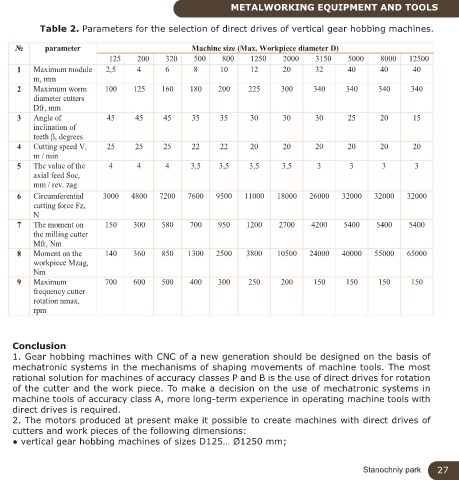

Table 2. Parameters for the selection of direct drives of vertical gear hobbing machines.

№ parameter Machine size (Max. Workpiece diameter D)

125 200 320 500 800 1250 2000 3150 5000 8000 12500

1 Maximum module 2,5 4 6 8 10 12 20 32 40 40 40

m, mm

2 Maximum worm 100 125 160 180 200 225 300 340 340 340 340

diameter cutters

Dfr, mm

3 Angle of 45 45 45 35 35 30 30 30 25 20 15

inclination of

teeth β, degrees

4 Cutting speed V, 25 25 25 22 22 20 20 20 20 20 20

m / min

5 The value of the 4 4 4 3,5 3,5 3,5 3,5 3 3 3 3

axial feed Soc,

mm / rev. zag

6 Circumferential 3000 4800 7200 7600 9500 11000 18000 26000 32000 32000 32000

cutting force Fz,

N

7 The moment on 150 300 580 700 950 1200 2700 4200 5400 5400 5400

the milling cutter

Mfr, Nm

8 Moment on the 140 360 850 1300 2500 3800 10500 24000 40000 55000 65000

workpiece Mzag,

Nm

9 Maximum 700 600 500 400 300 250 200 150 150 150 150

frequency cutter

rotation nmax,

rpm

Conclusion

1. Gear hobbing machines with CNC of a new generation should be designed on the basis of

mechatronic systems in the mechanisms of shaping movements of machine tools. The most

rational solution for machines of accuracy classes P and B is the use of direct drives for rotation

of the cutter and the work piece. To make a decision on the use of mechatronic systems in

machine tools of accuracy class A, more long-term experience in operating machine tools with

direct drives is required.

2. The motors produced at present make it possible to create machines with direct drives of

cutters and work pieces of the following dimensions:

● vertical gear hobbing machines of sizes D125… Ø1250 mm;

Stanochniy park 27