Page 12 - LOFT LIFE FLIPBOOK

P. 12

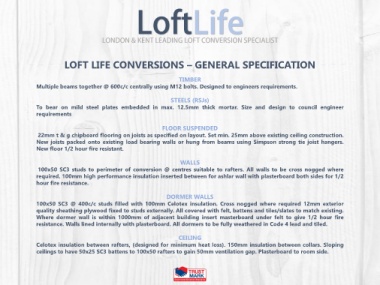

LOFT LIFE CONVERSIONS – GENERAL SPECIFICATION

TIMBER

Multiple beams together @ 600c/c centrally using M12 bolts. Designed to engineers requirements.

STEELS (RSJs)

To bear on mild steel plates embedded in max. 12.5mm thick mortar. Size and design to council engineer

requirements

FLOOR SUSPENDED

22mm t & g chipboard flooring on joists as specified on layout. Set min. 25mm above existing ceiling construction.

New joists packed onto existing load bearing walls or hung from beams using Simpson strong tie joist hangers.

New floor 1/2 hour fire resistant.

WALLS

100x50 SC3 studs to perimeter of conversion @ centres suitable to rafters. All walls to be cross nogged where

required. 100mm high performance insulation inserted between for ashlar wall with plasterboard both sides for 1/2

hour fire resistance.

DORMER WALLS

100x50 SC3 @ 400c/c studs filled with 100mm Celotex insulation. Cross nogged where required 12mm exterior

quality sheathing plywood fixed to studs externally. All covered with felt, battens and tiles/slates to match existing.

Where dormer wall is within 1000mm of adjacent building insert masterboard under felt to give 1/2 hour fire

resistance. Walls lined internally with plasterboard. All dormers to be fully weathered in Code 4 lead and tiled.

CEILING

Celotex insulation between rafters, (designed for minimum heat loss). 150mm insulation between collars. Sloping

ceilings to have 50x25 SC3 battens to 100x50 rafters to gain 50mm ventilation gap. Plasterboard to room side.