Page 27 - مشروع تخرج 1

P. 27

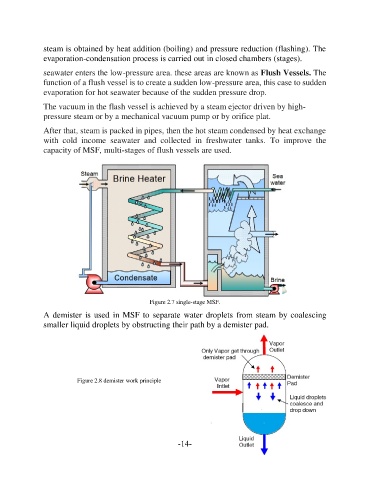

steam is obtained by heat addition (boiling) and pressure reduction (flashing). The

evaporation-condensation process is carried out in closed chambers (stages).

seawater enters the low-pressure area. these areas are known as Flush Vessels. The

function of a flush vessel is to create a sudden low-pressure area, this case to sudden

evaporation for hot seawater because of the sudden pressure drop.

The vacuum in the flash vessel is achieved by a steam ejector driven by high-

pressure steam or by a mechanical vacuum pump or by orifice plat.

After that, steam is packed in pipes, then the hot steam condensed by heat exchange

with cold income seawater and collected in freshwater tanks. To improve the

capacity of MSF, multi-stages of flush vessels are used.

Figure 2.7 single-stage MSF.

A demister is used in MSF to separate water droplets from steam by coalescing

smaller liquid droplets by obstructing their path by a demister pad.

Figure 2.8 demister work principle

-14-