Page 7 - June 2022 Track N Times

P. 7

TECHNICAL TRAINING

and spark blanket rolls are secured so they do not unroll during opera-

tions. Water system should also be tested to verify ditch and tie sprays

are adjusted correctly and supply adequate water.

The next inspection should be done by the Operations Superintendent

mid-day during a train delay. Everything except grind motors should be

left on or running for the inspection. Check all lights, low beam, high

beam, ditch lights, marker lights, strobes and brake light. Look at all

wheels for bluing caused by heavy braking or stuck brakes and look at

brake shoe condition. Make sure all traction motor cooling fans are run-

ning without excessive vibration or noise. Take a quick look over the

buggies, checking for leaks, spark blanket condition and buggy wheel con-

dition. If crew is changing stones, take a quick look inside the buggies,

particularly shoulder bolts on mod lifts, tilts and turnbuckles, and A

frame bolts. Take a quick look at all the common buss wires running be-

tween the cars. None should be

rubbing on the draw bars or look

damaged or melted in any way.

All dust blowers should be run- Ditch Light

ning without excessive vibration.

Walk by the engines and genera-

tors checking for leaks, excessive vibration and listening for odd sounds. Run

a quick test on tie and ditch sprays to make sure they are putting out ade-

quate water. Have the crew repair anything urgent while still on train delay,

especially if this is something that could cause machine delay later.

The first inspection done the

maintenance crew should be the

free spin. Modules with moderate

to severe vibration are the #1

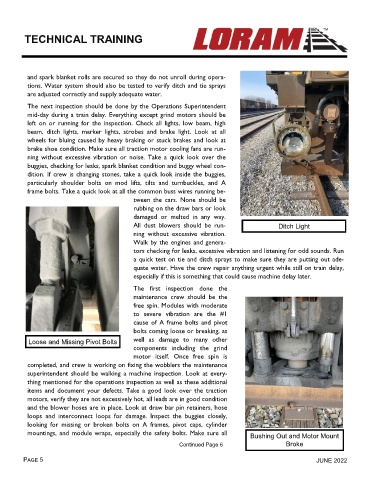

cause of A frame bolts and pivot

bolts coming loose or breaking, as

Loose and Missing Pivot Bolts well as damage to many other

components including the grind

motor itself. Once free spin is

completed, and crew is working on fixing the wobblers the maintenance

superintendent should be walking a machine inspection. Look at every-

thing mentioned for the operations inspection as well as these additional

items and document your defects. Take a good look over the traction

motors, verify they are not excessively hot, all leads are in good condition

and the blower hoses are in place. Look at draw bar pin retainers, hose

loops and interconnect loops for damage. Inspect the buggies closely,

looking for missing or broken bolts on A frames, pivot caps, cylinder

mountings, and module wraps, especially the safety bolts. Make sure all Bushing Out and Motor Mount

Continued Page 6 Broke

Page 5 JUNE 2022