Page 15 - March 2022 Track N Times

P. 15

DEPARTMENT FOCUS

Engineering—New Technology Continued

.

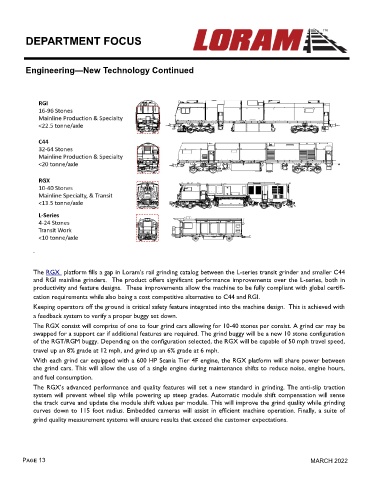

The RGX platform fills a gap in Loram’s rail grinding catalog between the L-series transit grinder and smaller C44

and RGI mainline grinders. The product offers significant performance improvements over the L-series, both in

productivity and feature designs. These improvements allow the machine to be fully compliant with global certifi-

cation requirements while also being a cost competitive alternative to C44 and RGI.

Keeping operators off the ground is critical safety feature integrated into the machine design. This is achieved with

a feedback system to verify a proper buggy set down.

The RGX consist will comprise of one to four grind cars allowing for 10-40 stones per consist. A grind car may be

swapped for a support car if additional features are required. The grind buggy will be a new 10 stone configuration

of the RGT/RGM buggy. Depending on the configuration selected, the RGX will be capable of 50 mph travel speed,

travel up an 8% grade at 12 mph, and grind up an 6% grade at 6 mph.

With each grind car equipped with a 600 HP Scania Tier 4F engine, the RGX platform will share power between

the grind cars. This will allow the use of a single engine during maintenance shifts to reduce noise, engine hours,

and fuel consumption.

The RGX’s advanced performance and quality features will set a new standard in grinding. The anti-slip traction

system will prevent wheel slip while powering up steep grades. Automatic module shift compensation will sense

the track curve and update the module shift values per module. This will improve the grind quality while grinding

curves down to 115 foot radius. Embedded cameras will assist in efficient machine operation. Finally, a suite of

grind quality measurement systems will ensure results that exceed the customer expectations.

Page 13 MARCH 2022