Page 11 - March 2022 Track N Times

P. 11

DEPARTMENT FOCUS

Engineering—New Technology

BY: Craig Block, Chief Engineer

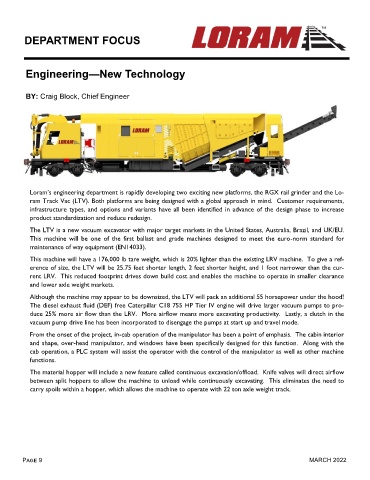

Loram’s engineering department is rapidly developing two exciting new platforms, the RGX rail grinder and the Lo-

ram Track Vac (LTV). Both platforms are being designed with a global approach in mind. Customer requirements,

infrastructure types, and options and variants have all been identified in advance of the design phase to increase

product standardization and reduce redesign.

The LTV is a new vacuum excavator with major target markets in the United States, Australia, Brazil, and UK/EU.

This machine will be one of the first ballast and grade machines designed to meet the euro-norm standard for

maintenance of way equipment (EN14033).

This machine will have a 176,000 lb tare weight, which is 20% lighter than the existing LRV machine. To give a ref-

erence of size, the LTV will be 25.75 feet shorter length, 2 feet shorter height, and 1 foot narrower than the cur-

rent LRV. This reduced footprint drives down build cost and enables the machine to operate in smaller clearance

and lower axle weight markets.

Although the machine may appear to be downsized, the LTV will pack an additional 55 horsepower under the hood!

The diesel exhaust fluid (DEF) free Caterpillar C18 755 HP Tier IV engine will drive larger vacuum pumps to pro-

duce 25% more air flow than the LRV. More airflow means more excavating productivity. Lastly, a clutch in the

vacuum pump drive line has been incorporated to disengage the pumps at start up and travel mode.

From the onset of the project, in-cab operation of the manipulator has been a point of emphasis. The cabin interior

and shape, over-head manipulator, and windows have been specifically designed for this function. Along with the

cab operation, a PLC system will assist the operator with the control of the manipulator as well as other machine

functions.

The material hopper will include a new feature called continuous excavation/offload. Knife valves will direct airflow

between split hoppers to allow the machine to unload while continuously excavating. This eliminates the need to

carry spoils within a hopper, which allows the machine to operate with 22 ton axle weight track.

Page 9 MARCH 2022