Page 67 - Shaping A Sustainable Future

P. 67

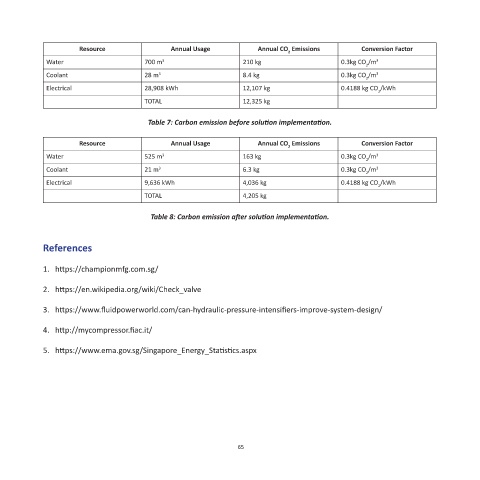

Resource Annual Usage Annual CO Emissions Conversion Factor

2

Water 700 m 3 210 kg 0.3kg CO /m 3

2

Coolant 28 m 3 8.4 kg 0.3kg CO /m 3

2

Electrical 28,908 kWh 12,107 kg 0.4188 kg CO /kWh

2

TOTAL 12,325 kg

Table 7: Carbon emission before solution implementation.

Resource Annual Usage Annual CO Emissions Conversion Factor

2

Water 525 m 163 kg 0.3kg CO /m 3

3

2

Coolant 21 m 3 6.3 kg 0.3kg CO /m 3

2

Electrical 9,636 kWh 4,036 kg 0.4188 kg CO /kWh

2

TOTAL 4,205 kg

Table 8: Carbon emission after solution implementation.

References

1. https://championmfg.com.sg/

2. https://en.wikipedia.org/wiki/Check_valve

3. https://www.fluidpowerworld.com/can-hydraulic-pressure-intensifiers-improve-system-design/

4. http://mycompressor.fiac.it/

5. https://www.ema.gov.sg/Singapore_Energy_Statistics.aspx

65