Page 72 - Shaping A Sustainable Future

P. 72

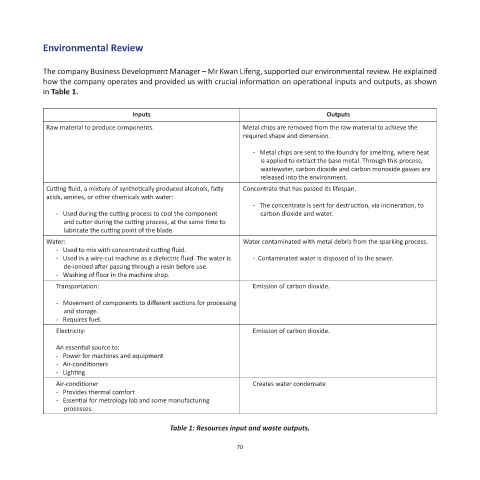

Environmental Review

The company Business Development Manager – Mr Kwan Lifeng, supported our environmental review. He explained

how the company operates and provided us with crucial information on operational inputs and outputs, as shown

in Table 1.

Inputs Outputs

Raw material to produce components. Metal chips are removed from the raw material to achieve the

required shape and dimension.

- Metal chips are sent to the foundry for smelting, where heat

is applied to extract the base metal. Through this process,

wastewater, carbon dioxide and carbon monoxide gasses are

released into the environment.

Cutting fluid, a mixture of synthetically produced alcohols, fatty Concentrate that has passed its lifespan.

acids, amines, or other chemicals with water:

- The concentrate is sent for destruction, via incineration, to

- Used during the cutting process to cool the component carbon dioxide and water.

and cutter during the cutting process, at the same time to

lubricate the cutting point of the blade.

Water: Water contaminated with metal debris from the sparking process.

- Used to mix with concentrated cutting fluid.

- Used in a wire-cut machine as a dielectric fluid. The water is - Contaminated water is disposed of to the sewer.

de-ionized after passing through a resin before use.

- Washing of floor in the machine shop.

Transportation: Emission of carbon dioxide.

- Movement of components to different sections for processing

and storage.

- Requires fuel.

Electricity: Emission of carbon dioxide.

An essential source to:

- Power for machines and equipment

- Air-conditioners

- Lighting

Air-conditioner Creates water condensate

- Provides thermal comfort

- Essential for metrology lab and some manufacturing

processes.

Table 1: Resources input and waste outputs.

70