Page 75 - Shaping A Sustainable Future

P. 75

Good Environmental Practices 4R – Reduce, Reuse, Recycle, Recreate

There are some existing good environmental practices The Environmental Sustainability team opted to evaluate

already implemented at CKE Manufacturing. the operation of air-conditioners and the potential to

enhance environmental performance. Based on trial

For example, waste types are appropriately categorized data collected, our team evaluated ways to improve

for follow-up actions. Waste bins are clearly labelled the function of the air-conditioners and excellent air

and used to segregate metal wastes and general wastes. circulation. We also explored ways to recycle and reuse

Metals chips are sent for recycling and reuse. The water condensate generated from air-conditioners.

company is also working with the Singapore Institute

of Manufacturing Technology (SIMTech) to improve its

Manufacturing Control Tower (MCT) platform. This has Eco-Solutions

enabled the detection of defects in real-time, which

results in the reduction of metal waste. Eco-Solution 1: Operation of Air-

conditioning Units

Presentation of Data

Research has been conducted to determine possible

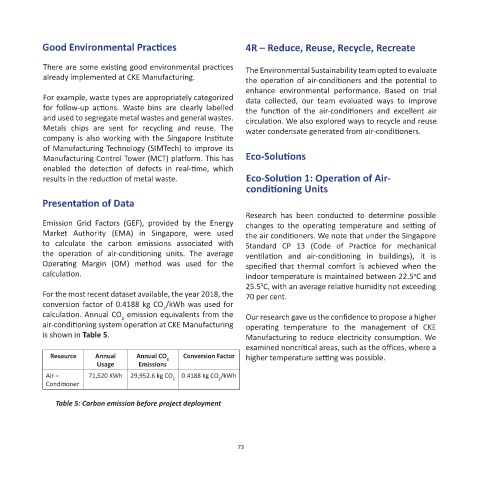

Emission Grid Factors (GEF), provided by the Energy changes to the operating temperature and setting of

Market Authority (EMA) in Singapore, were used the air conditioners. We note that under the Singapore

to calculate the carbon emissions associated with Standard CP 13 (Code of Practice for mechanical

the operation of air-conditioning units. The average ventilation and air-conditioning in buildings), it is

Operating Margin (OM) method was used for the specified that thermal comfort is achieved when the

calculation. indoor temperature is maintained between 22.5 C and

o

25.5 C, with an average relative humidity not exceeding

0

For the most recent dataset available, the year 2018, the 70 per cent.

conversion factor of 0.4188 kg CO /kWh was used for

2

calculation. Annual CO emission equivalents from the Our research gave us the confidence to propose a higher

2

air-conditioning system operation at CKE Manufacturing operating temperature to the management of CKE

is shown in Table 5. Manufacturing to reduce electricity consumption. We

examined noncritical areas, such as the offices, where a

Resource Annual Annual CO 2 Conversion Factor higher temperature setting was possible.

Usage Emissions

Air – 71,520 KWh 29,952.6 kg CO 2 0.4188 kg CO /kWh

2

Conditioner

Table 5: Carbon emission before project deployment

73