Page 139 - Towards A Sustainable Future 2024

P. 139

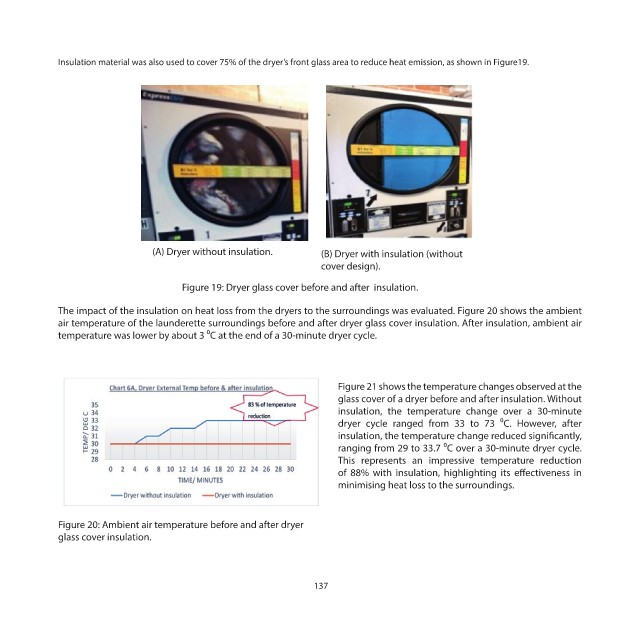

Insulation material was also used to cover 75% of the dryer’s front glass area to reduce heat emission, as shown in Figure19.

(A) Dryer without insulation. (B) Dryer with insulation (without

cover design).

Figure 19: Dryer glass cover before and after insulation.

The impact of the insulation on heat loss from the dryers to the surroundings was evaluated. Figure 20 shows the ambient

air temperature of the launderette surroundings before and after dryer glass cover insulation. After insulation, ambient air

temperature was lower by about 3 ⁰C at the end of a 30-minute dryer cycle.

Figure 21 shows the temperature changes observed at the

glass cover of a dryer before and after insulation. Without

insulation, the temperature change over a 30-minute

dryer cycle ranged from 33 to 73 ⁰C. However, after

insulation, the temperature change reduced significantly,

ranging from 29 to 33.7 ⁰C over a 30-minute dryer cycle.

This represents an impressive temperature reduction

of 88% with insulation, highlighting its effectiveness in

minimising heat loss to the surroundings.

Figure 20: Ambient air temperature before and after dryer

glass cover insulation.

137