Page 140 - Towards A Sustainable Future 2024

P. 140

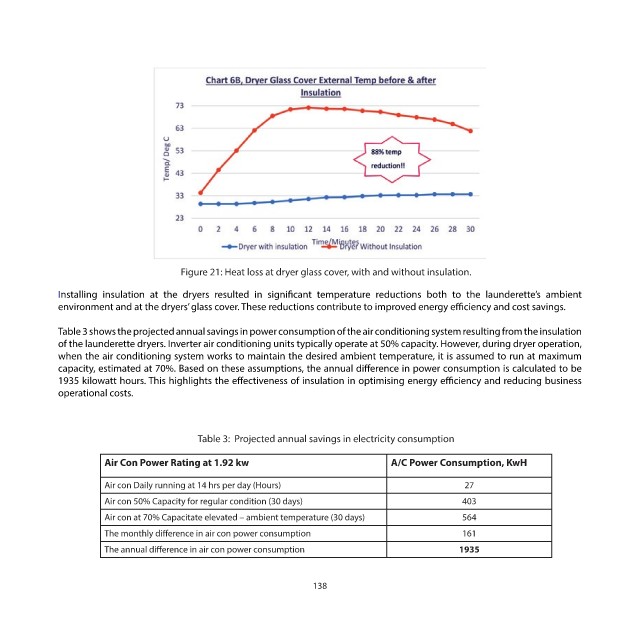

Figure 21: Heat loss at dryer glass cover, with and without insulation.

Installing insulation at the dryers resulted in significant temperature reductions both to the launderette’s ambient

environment and at the dryers’ glass cover. These reductions contribute to improved energy efficiency and cost savings.

Table 3 shows the projected annual savings in power consumption of the air conditioning system resulting from the insulation

of the launderette dryers. Inverter air conditioning units typically operate at 50% capacity. However, during dryer operation,

when the air conditioning system works to maintain the desired ambient temperature, it is assumed to run at maximum

capacity, estimated at 70%. Based on these assumptions, the annual difference in power consumption is calculated to be

1935 kilowatt hours. This highlights the effectiveness of insulation in optimising energy efficiency and reducing business

operational costs.

Table 3: Projected annual savings in electricity consumption

Air Con Power Rating at 1.92 kw A/C Power Consumption, KwH

Air con Daily running at 14 hrs per day (Hours) 27

Air con 50% Capacity for regular condition (30 days) 403

Air con at 70% Capacitate elevated – ambient temperature (30 days) 564

The monthly difference in air con power consumption 161

The annual difference in air con power consumption 1935

138