Page 141 - Towards A Sustainable Future 2024

P. 141

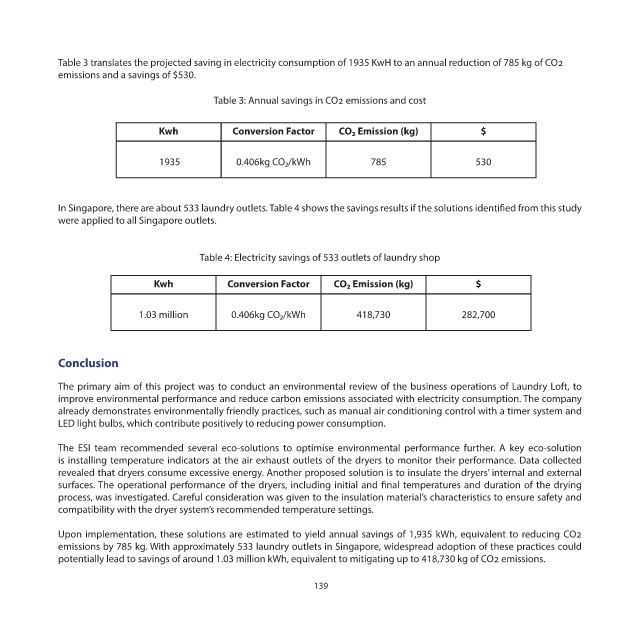

Table 3 translates the projected saving in electricity consumption of 1935 KwH to an annual reduction of 785 kg of CO2

emissions and a savings of $530.

Table 3: Annual savings in CO2 emissions and cost

Kwh Conversion Factor CO₂ Emission (kg) $

1935 0.406kg CO₂/kWh 785 530

In Singapore, there are about 533 laundry outlets. Table 4 shows the savings results if the solutions identified from this study

were applied to all Singapore outlets.

Table 4: Electricity savings of 533 outlets of laundry shop

Kwh Conversion Factor CO₂ Emission (kg) $

1.03 million 0.406kg CO₂/kWh 418,730 282,700

Conclusion

The primary aim of this project was to conduct an environmental review of the business operations of Laundry Loft, to

improve environmental performance and reduce carbon emissions associated with electricity consumption. The company

already demonstrates environmentally friendly practices, such as manual air conditioning control with a timer system and

LED light bulbs, which contribute positively to reducing power consumption.

The ESI team recommended several eco-solutions to optimise environmental performance further. A key eco-solution

is installing temperature indicators at the air exhaust outlets of the dryers to monitor their performance. Data collected

revealed that dryers consume excessive energy. Another proposed solution is to insulate the dryers’ internal and external

surfaces. The operational performance of the dryers, including initial and final temperatures and duration of the drying

process, was investigated. Careful consideration was given to the insulation material’s characteristics to ensure safety and

compatibility with the dryer system’s recommended temperature settings.

Upon implementation, these solutions are estimated to yield annual savings of 1,935 kWh, equivalent to reducing CO2

emissions by 785 kg. With approximately 533 laundry outlets in Singapore, widespread adoption of these practices could

potentially lead to savings of around 1.03 million kWh, equivalent to mitigating up to 418,730 kg of CO2 emissions.

139