Page 179 - Towards A Sustainable Future 2024

P. 179

SPEQS Manufacturing Pte Ltd

Introduction

Singapore Precision Engineering Quality Service (SPEQS) specialises in delivering top-tier engineering solutions across

various industries, including Aerospace, Oil and Gas, Healthcare, Security, and Electro-mechanical sectors. Its services

encompass computer numerical control (CNC) machining, customised product design and development, prototyping, and

assembly work, as well as supplementary services such as heat treatment chemical/surface finishing. With a primary focus on

CNC machining of bespoke products crafted from steel, iron, aluminium, and plastic, SPEQS has a diverse array of machinery .

Environmental Review

During the environmental review of SPEQS, the ESI team noted the substantial usage of water and coolant within SPEQS'

operations, primarily used to cool down metals during CNC processing. This serves the dual purpose of preserving the lifespan

of cutting tools by averting overheating, while safeguarding the integrity of the processed products. The drills utilised in the

CNC process are equipped with motors, necessitating oil lubrication. Unfortunately, this oil inadvertently seeps into the

coolant, increasing viscosity and rendering it less effective for its intended purpose.

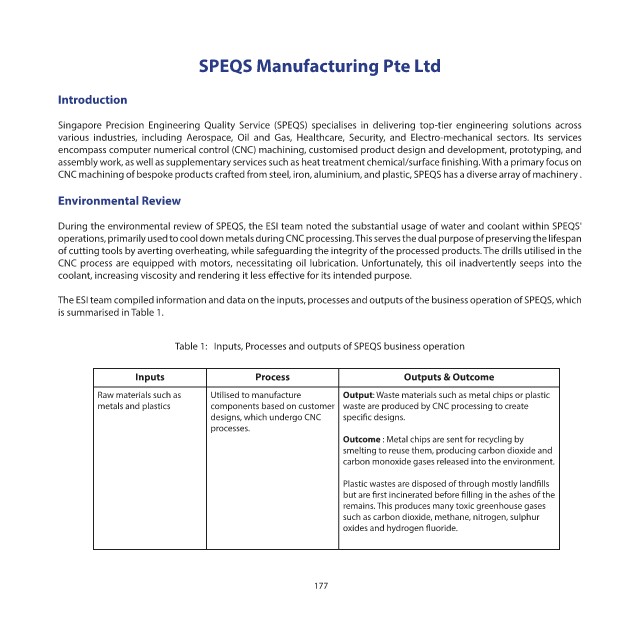

The ESI team compiled information and data on the inputs, processes and outputs of the business operation of SPEQS, which

is summarised in Table 1.

Table 1: Inputs, Processes and outputs of SPEQS business operation

Inputs Process Outputs & Outcome

Raw materials such as Utilised to manufacture Output: Waste materials such as metal chips or plastic

metals and plastics components based on customer waste are produced by CNC processing to create

designs, which undergo CNC specific designs.

processes.

Outcome : Metal chips are sent for recycling by

smelting to reuse them, producing carbon dioxide and

carbon monoxide gases released into the environment.

Plastic wastes are disposed of through mostly landfills

but are first incinerated before filling in the ashes of the

remains. This produces many toxic greenhouse gases

such as carbon dioxide, methane, nitrogen, sulphur

oxides and hydrogen fluoride.

177