Page 182 - Towards A Sustainable Future 2024

P. 182

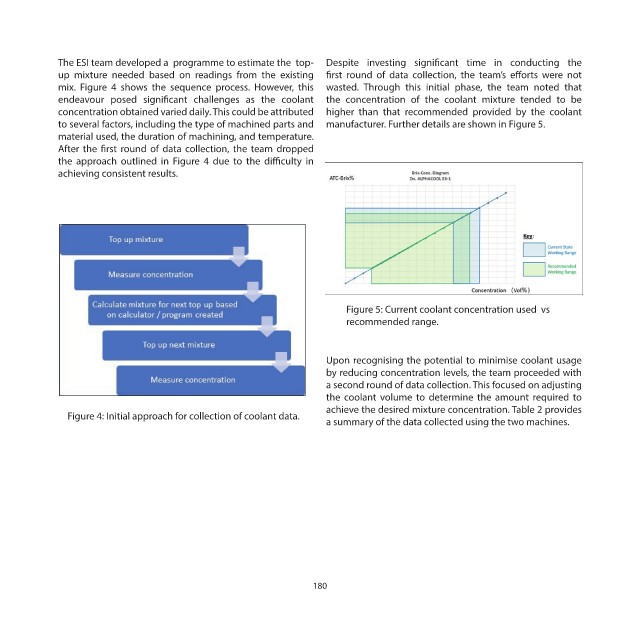

The ESI team developed a programme to estimate the top- Despite investing significant time in conducting the

up mixture needed based on readings from the existing first round of data collection, the team’s efforts were not

mix. Figure 4 shows the sequence process. However, this wasted. Through this initial phase, the team noted that

endeavour posed significant challenges as the coolant the concentration of the coolant mixture tended to be

concentration obtained varied daily. This could be attributed higher than that recommended provided by the coolant

to several factors, including the type of machined parts and manufacturer. Further details are shown in Figure 5.

material used, the duration of machining, and temperature.

After the first round of data collection, the team dropped

the approach outlined in Figure 4 due to the difficulty in

achieving consistent results.

Figure 5: Current coolant concentration used vs

recommended range.

Upon recognising the potential to minimise coolant usage

by reducing concentration levels, the team proceeded with

a second round of data collection. This focused on adjusting

the coolant volume to determine the amount required to

achieve the desired mixture concentration. Table 2 provides

Figure 4: Initial approach for collection of coolant data.

a summary of the data collected using the two machines.

180