Page 183 - Towards A Sustainable Future 2024

P. 183

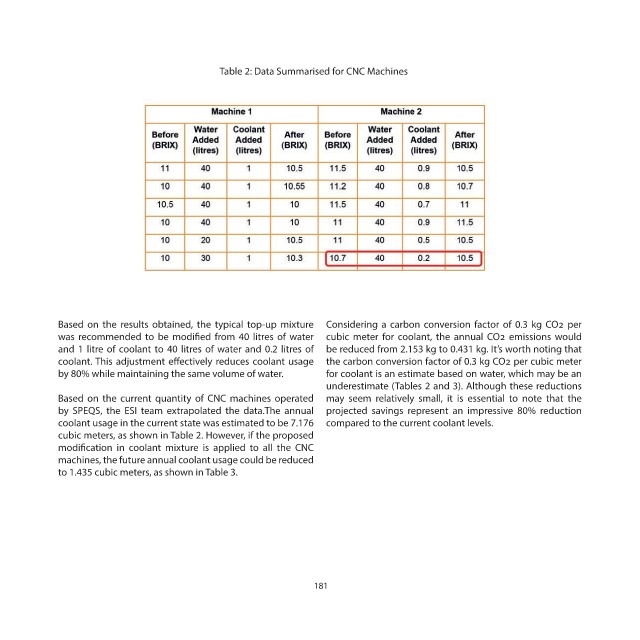

Table 2: Data Summarised for CNC Machines

Based on the results obtained, the typical top-up mixture Considering a carbon conversion factor of 0.3 kg CO2 per

was recommended to be modified from 40 litres of water cubic meter for coolant, the annual CO2 emissions would

and 1 litre of coolant to 40 litres of water and 0.2 litres of be reduced from 2.153 kg to 0.431 kg. It’s worth noting that

coolant. This adjustment effectively reduces coolant usage the carbon conversion factor of 0.3 kg CO2 per cubic meter

by 80% while maintaining the same volume of water. for coolant is an estimate based on water, which may be an

underestimate (Tables 2 and 3). Although these reductions

Based on the current quantity of CNC machines operated may seem relatively small, it is essential to note that the

by SPEQS, the ESI team extrapolated the data.The annual projected savings represent an impressive 80% reduction

coolant usage in the current state was estimated to be 7.176 compared to the current coolant levels.

cubic meters, as shown in Table 2. However, if the proposed

modification in coolant mixture is applied to all the CNC

machines, the future annual coolant usage could be reduced

to 1.435 cubic meters, as shown in Table 3.

181