Page 222 - Towards A Sustainable Future 2024

P. 222

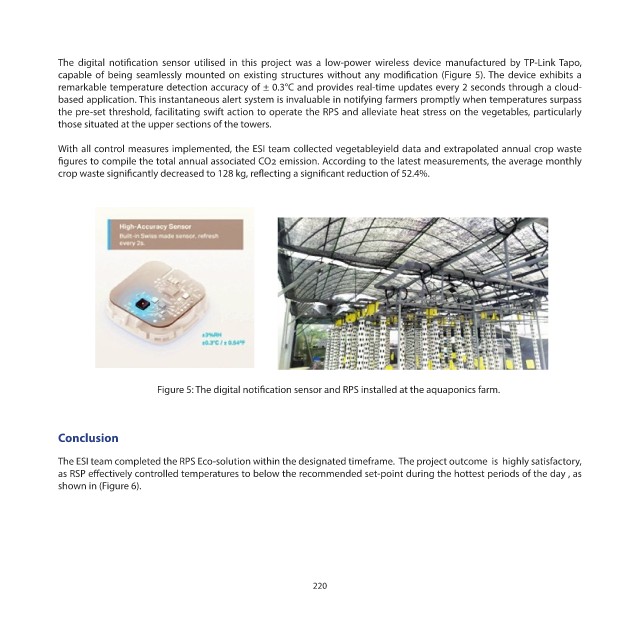

The digital notification sensor utilised in this project was a low-power wireless device manufactured by TP-Link Tapo,

capable of being seamlessly mounted on existing structures without any modification (Figure 5). The device exhibits a

remarkable temperature detection accuracy of ± 0.3°C and provides real-time updates every 2 seconds through a cloud-

based application. This instantaneous alert system is invaluable in notifying farmers promptly when temperatures surpass

the pre-set threshold, facilitating swift action to operate the RPS and alleviate heat stress on the vegetables, particularly

those situated at the upper sections of the towers.

With all control measures implemented, the ESI team collected vegetableyield data and extrapolated annual crop waste

figures to compile the total annual associated CO2 emission. According to the latest measurements, the average monthly

crop waste significantly decreased to 128 kg, reflecting a significant reduction of 52.4%.

Figure 5: The digital notification sensor and RPS installed at the aquaponics farm.

Conclusion

The ESI team completed the RPS Eco-solution within the designated timeframe. The project outcome is highly satisfactory,

as RSP effectively controlled temperatures to below the recommended set-point during the hottest periods of the day , as

shown in (Figure 6).

220