Page 37 - Towards A Sustainable Future 2024

P. 37

Carrier Transicold Pte Ltd

Introduction

Carrier Transicold, a division of Carrier Corporation,

specialises in manufacturing transport refrigeration systems,

with expertise in assembling and testing refrigeration

equipment for containers in trucks and trailers. The

manufacturing plant in Singapore started its operation in

1993, and is located on the western side of Singapore. The

plant supplies refrigeration units for transport to different

parts of the world.

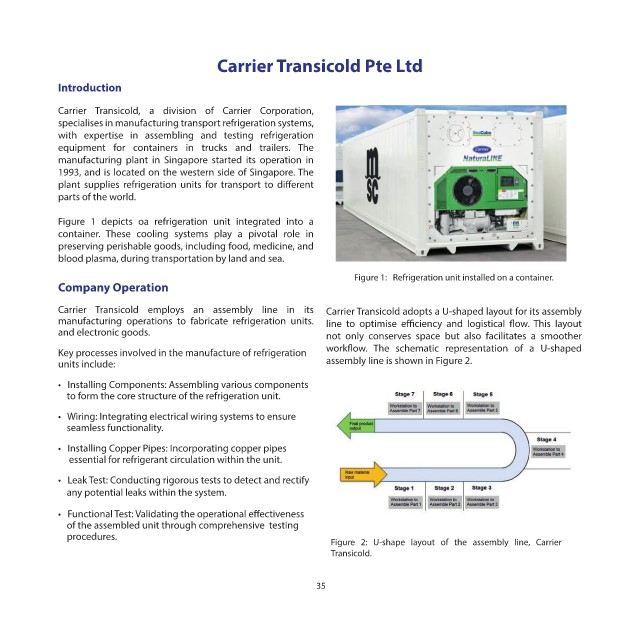

Figure 1 depicts oa refrigeration unit integrated into a

container. These cooling systems play a pivotal role in

preserving perishable goods, including food, medicine, and

blood plasma, during transportation by land and sea.

Figure 1: Refrigeration unit installed on a container.

Company Operation

Carrier Transicold employs an assembly line in its Carrier Transicold adopts a U-shaped layout for its assembly

manufacturing operations to fabricate refrigeration units. line to optimise efficiency and logistical flow. This layout

and electronic goods. not only conserves space but also facilitates a smoother

Key processes involved in the manufacture of refrigeration workflow. The schematic representation of a U-shaped

units include: assembly line is shown in Figure 2.

• Installing Components: Assembling various components

to form the core structure of the refrigeration unit.

• Wiring: Integrating electrical wiring systems to ensure

seamless functionality.

• Installing Copper Pipes: Incorporating copper pipes

essential for refrigerant circulation within the unit.

• Leak Test: Conducting rigorous tests to detect and rectify

any potential leaks within the system.

• Functional Test: Validating the operational effectiveness

of the assembled unit through comprehensive testing

procedures.

Figure 2: U-shape layout of the assembly line, Carrier

Transicold.

35