Page 43 - Towards A Sustainable Future 2024

P. 43

Figure 8: Base Support.

By transitioning to aluminium base supports with this innovative design feature, a sustainable eco-solution was identified

that reduces environmental impact and enhances operational efficiency and safety. Given that a minimum quantity of 500

base supports is required to accommodate average daily production needs, and assuming a reduction in fabrication cost of

$575 per unit, the initial cost for fabrication of 500 units x $575 = $287,500.

ECO Solution 2: Reuse Condensate to Cool Electronics Devices

Condensate, a by-product of the testing process, is essentially distilled water with minimal mineral content, making it

significantly purer than tap water. Recognising its potential as an alternative water source for general use, the ESI team

proposed repurposing the condensate to cool the electronic devices utilised during brazing to reduce water consumption

and minimise environmental impact while maintaining operational efficiency.

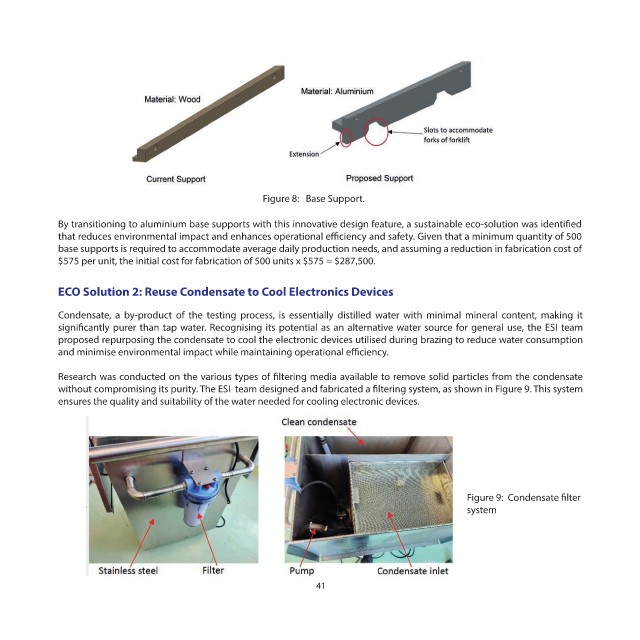

Research was conducted on the various types of filtering media available to remove solid particles from the condensate

without compromising its purity. The ESI team designed and fabricated a filtering system, as shown in Figure 9. This system

ensures the quality and suitability of the water needed for cooling electronic devices.

Figure 9: Condensate filter

system

41