Page 22 - QR CIMAR LASER SCREED

P. 22

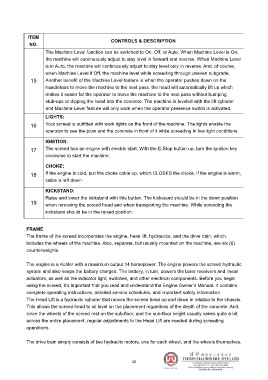

ITEM CONTROLS & DESCRIPTION

NO.

The Machine Level function can be switched to On, Off, or Auto. When Machine Level is On,

15 the machine will continuously adjust to stay level in forward and reverse. When Machine Level

is in Auto, the machine will continuously adjust to stay level only in reverse. And, of course,

16 when Machine Level if Off, the machine level while screeding through uneven subgrade.

Another benefit of the Machine Level feature is when the operator pushes down on the

handlebars to move the machine to the next pass, the head will automatically lift up which

makes it easier for the operator to move the machine to the next pass without bumping

stub-ups or dipping the head into the concrete. The machine is leveled with the lift cylinder

and Machine Level feature will only work when the operator presence switch is activated.

LIGHTS:

Your screed is outfitted with work lights on the front of the machine. The lights enable the

operator to see the plow and the concrete in front of it while screeding in low light conditions.

IGNITION:

17 The screed has an engine with electric start. With the E-Stop button up, turn the ignition key

clockwise to start the machine.

CHOKE:

18 If the engine is cold, pull the choke cable up, which CLOSES the choke. If the engine is warm,

cable is left down.

KICKSTAND:

Raise and lower the kickstand with this button. The kickstand should be in the down position

19 when removing the screed head and when transporting the machine. While screeding the

kickstand should be in the raised position.

FRAME

The frame of the screed incorporates the engine, head lift, hydraulics, and the drive train, which

includes the wheels of the machine. Also, separate, but usually mounted on the machine, are six (6)

counterweights.

The engine is a Kohler with a maximum output 14 horsepower. The engine powers the screed hydraulic

system and also keeps the battery charges. The battery, in turn, powers the laser receivers and linear

actuators, as well as the indicator light, switches, and other electrical components. Before you begin

using the screed, it’s important that you read and understand the Engine Owner’s Manual. It contains

complete operating instructions, detailed service schedules, and important safety information.

The Head Lift is a hydraulic cylinder that moves the screed head up and down in relation to the chassis.

This allows the screed head to sit level on the placement regardless of the depth of the concrete. And,

since the wheels of the screed rest on the sub-floor, and the sub-floor height usually varies quite a bit

across the entire placement, regular adjustments to the Head Lift are needed during screeding

operations.

The drive train simply consists of two hydraulic motors, one for each wheel, and the wheels themselves.

20